In today’s fast-moving world, industries need tools that work quickly, safely, and cleanly. That’s where the high-precision ultrasonic welding machine comes in. It joins materials using high-frequency sound waves, not heat or glue. This makes it a smart, eco-friendly choice for many factories. It works fast, leaves no mess, and creates strong bonds between parts. From cars to electronics and medical devices, ultrasonic welding is now a trusted method in many industries.

Let’s learn more about high-frequency welding machines, their special features, and why they are a top choice for clean and reliable welding.

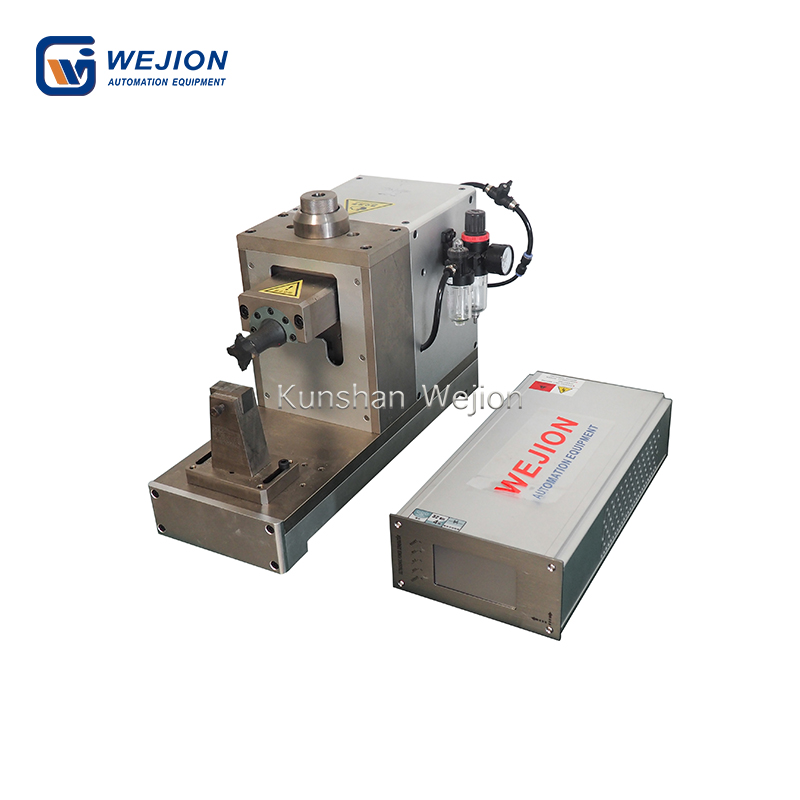

Top Quality Ultrasonic Welding Equipment

If you’re seeking out the best ultrasonic welding machine, these 3 machines deliver notable results. They are perfect for industries like automotive, electronics, and battery manufacturing. Each gadget makes use of ultrasonic technology to create the best bonds without the use of glue, flame, or higher heat. That way, quicker workings, less power use, and cleaner results. Let’s take a more in-depth look at these effective machines.

WC-U20 Wire Harness Welding Machine

The WC-U20 Ultrasonic Wire Harness Welding Machine is constructed to handle wire harnesses from 0.5mm² to 20mm². It runs at 20kHz with 3000W electricity. This machine is right for the automobile industry, where speed and safety depend most. It creates clean, stable joints without unfavourable wires. Its green layout enables the store to generate electricity and cuts down on waste. This makes it an excellent choice for high-volume jobs.

WU-M2030A Metal Welding Machine

Next is the WU-M2030A Ultrasonic Metal Welding Machine. This one also works at 3000W and 20kHz. It welds wire harnesses similar to the WC-U20 but adds extra flexibility. It’s extraordinary for energy batteries, home equipment, and electronics. What makes it special is its couple of welding modes. You can alter it effortlessly to suit special responsibilities. It gives strong welds with low heat, so your elements stay secure and best.

WU-T2030 Copper Tube Welding Machine

The WU-T2030 Ultrasonic Copper Tube Welding Machine is best for welding copper tubes. It makes use of ultrasonic power to weld speedily and neatly. This machine is straightforward to use and gives a solid weld every time. It works properly for making easy joints in cooling structures or plumbing, in which copper tubes are commonplace.

What Is an Ultrasonic Welding Machine?

An ultrasonic welding machine is a device that joins materials using sound waves. It no longer uses warmth like conventional welding. Instead, it makes use of vibrations at a high frequency—generally above 20,000 times acwireing to second. These sound waves are so fast that they generate heat through friction right where the two parts touch. That small amount of heat melts the edges, and the components stick together tightly when cooled.

Here’s how it works step-by-step. First, two pieces of material, like plastic or metal, are placed together. The precision ultrasonic joining tool then sends the ultrasonic vibrations through one element. The sound waves attain the point where the 2 substances meet. There, the friction turns into warmth, which melts the floor. When the vibration stops, the melted elements cool and become one solid piece.

Features That Ensure Fast and Precise Welding Performance

A high-precision ultrasonic welding machine comes with features that make it fast and accurate.

One of the most important elements is the transducer. It modifies electric strength into sound strength. The sound travels via a tool called a horn or sonotrode, which touches the fabric. This eco-friendly ultrasonic weld technology is designed to suit the components being welded. Because the device could be very genuine, it ensures the best, even bond whenever.

Another key function is the management gadget. It helps you to set the time, strain, and strength for every activity. In this manner, you could adjust the system for distinctive substances and sizes. The manipulation system makes sure each weld is identical, which is vital in factories that make heaps of product each day.

The ultrasonic plastic welder works fast. Most welds take much less than 2d to finish. This allows shop time and boosts production velocity. And since it doesn’t want glue, screws, or warmth from a flame, there are fewer steps and fewer elements needed.

Many machines have protection features that prevent the device if something is inaccurate. This protects workers and keeps the system in appropriate shape. These capabilities make ultrasonic welders a smart and secure choice for present manufacturing.

Why Ultrasonic Welding Offers a Clean and Eco-Friendly Solution

One large purpose of industries that use ultrasonic welding machines is that it’s smooth. There’s no smoke, no open flame, and no dangerous fumes. It also doesn’t use glue or chemical substances, which means that no sticky mess. That’s higher for workers and the planet.

The method is likewise power-efficient. Since every weld takes only a tiny bit of electricity and just a 2nd or two to finish, it saves a significant amount of electricity over the years. This helps factories cut down on energy use and lower their fees.

Another advantage isn’t no waste. The system handiest melts a small part of the fabric. There’s no extra glue, no screws, and no leftover components. Everything suits tightly and smartly. This reduces trash and enables holding the manufacturing area easily.

Because ultrasonic welding is so clean and stable, it’s regularly utilised in places where hygiene may be very crucial, like in scientific devices or food packaging. It’s a fantastic way to make products that meet high protection requirements without hurting the environment.

Top Applications in Automotive, Electronics, and Medical Industries

Ultrasonic welding machines are used in lots of industries due to the fact they offer strong, fast, and easy bonds. In the auto industry, they assist in connecting elements like dashboards, door panels, or even electrical wires. These industrial ultrasonic bonding systems make sure components fit tightly and don’t move or come aside while the automobile is in use.

In the electronics industry, ultrasonic welding is used for becoming a member of small parts like circuit boards, sensors, and wire harnesses. These tiny elements need actual welding. The device’s precision makes it best for this kind of work. It also helps prevent away from heat damage, which could harm sensitive electronics.

In the medical field, cleanliness is prime. Ultrasonic welding is ideal for making items like face masks, blood filters, IV tubes, and various tools. Since no glue or flames are used, the very last product is safe to use on or in the frame. It also facilitates keeping equipment sterile and free from germs.

Not to be counted in the industry, this welding approach allows companies to make better, cleaner, and more secure products. That’s why an increasing number of corporations are the usage of ultrasonic welding in their operations.

Choosing the Right Ultrasonic Welding Machine

Choosing the proper non-contact welding equipment depends on a few things.

- Reflect on the materials you need to weld. Most machines are best for plastics, but if you’re operating with skinny metals or wire harnesses, you’ll want a greater powerful system with the right frequency.

- Bear in mind the scale and form of your components. Some machines are built for small, distinctive workings. Others can cope with large or extra complicated shapes. Make certain the machine’s horn can be fashioned to fit your parts. A desirable, in shape manner, a more potent bond.

- Another point to check is the frequency and energy stage. Higher frequencies are pleasant for small components and skinny substances. Lower frequencies work better for thick or large components. A system with adjustable settings is useful because you may use it for many different jobs.

- Look for automation alternatives. Some ultrasonic welders can work with robot hands or be a part of a complete manufacturing line. This makes things faster and less complicated in case you’re generating large quantities of product every day.

Buy a Reliable and High-Quality Ultrasonic Machine

If you’re seeking out a reliable automated ultrasonic welding solution, one of the top places to head is Kunshan Weijiang Automation Equipment Co., Ltd. This employer is known for making extremely good welding machines and full automation solutions. They also offer best-in-class wire processing and harness meeting machines, which might be best for industries that want easy, brief, and secure bonding.

Kunshan Weijiang focuses on smart technology and user-friendly designs. Their ultrasonic welding machines are made with the best parts and contemporary capabilities. This approach much less downtime, quicker workings, and better effects. Whether you’re running in automobile, clinical, or electronics, their machines can be shaped to fit your product desires.

They also care approximately customer service. The organisation helps you set up the gadget and teaches your team the way to use it. If something breaks or you need help, their service group is ready to help you.

You can find their form of structures online or speak to their experts for custom answers. If you want fast, clean, and smart ultrasonic welding, Kunshan Weijiang Automation Equipment Co., Ltd. Is the name you may agree with?