Wires are very important in our daily lives. They power our cars, phones, machines, and even home appliances. But wires are not safe unless they are connected the right way. A weak connection can break or cause serious problems.

That is why industries now use advanced machines to handle wires. One of the best tools is the automatic three-terminal combined crimping machine. This machine makes wire work fast, safe, and very accurate. It can crimp three terminals at the same time and saves a lot of time and effort.

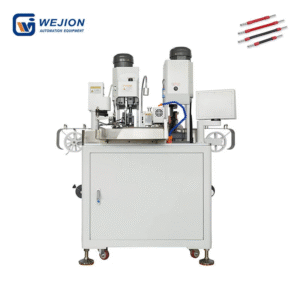

Automatic 3-Terminal Crimping Machine (TA-T01)

The TA-T01 Automatic Three-Terminal Combined Crimping Machine is designed to make wire processing faster, smarter, and more accurate.

This advanced dual-wire terminal machine offers flexible crimping options, including single, double, and three-terminal crimping. It works with different types of terminals, such as horizontal, vertical, and flag-shaped, making it a perfect fit for complex wire harness projects.

One of the biggest strengths of the TA-T01 is its precise digital control system. Operators can easily set cutting length, stripping depth, and crimping details on the touchscreen. Automatic wire crimping equipment ensures every wire is processed with the same accuracy, improving quality and reducing waste.

The TA-T01 also offers flexible expansion options. For longer wires, a conveyor belt keeps wires straight and neat. The optional pressure management system adds extra safety by stopping the machine if any issue is detected.

Made with a stable modular design, this machine is easy to operate, maintain and walk for a long time. With the production speed of 4,800 pieces per hour, TA-T01 is a reliable, high-performance option for industries that require efficiency and accuracy in wire crimping.

How a three-terminal combined crimping machine works

Crimping means pressing a wire into a terminal so that it stays together. It creates a strong bond that safely bears strength or signs.

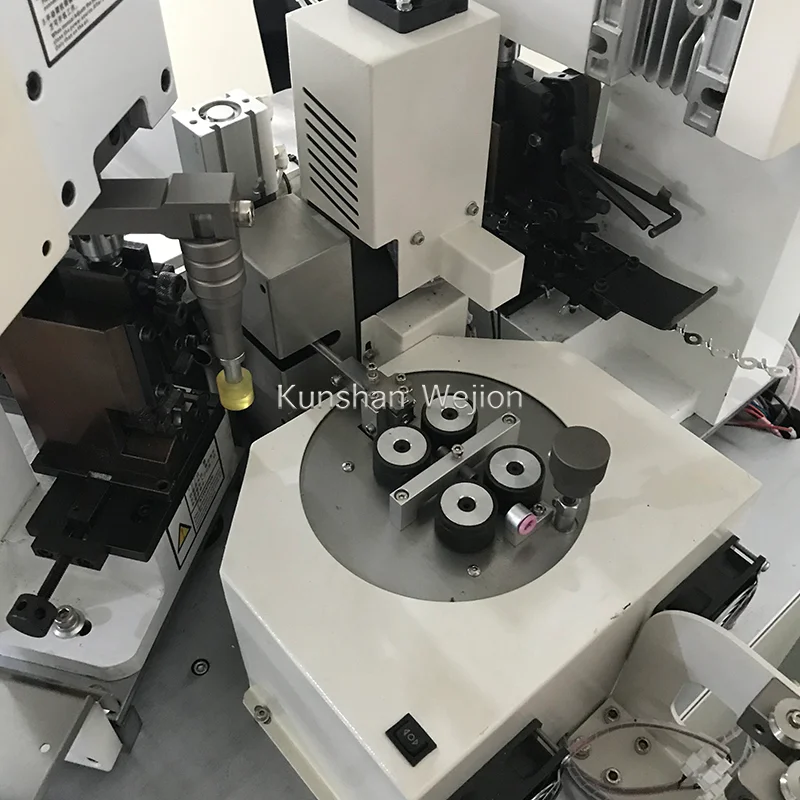

A three-terminal combined crimping machine can handle three wires at a single go. First, it strips the wire, then it puts the wire into the terminal, and finally, it applies the right pressure to lock them together. The entire process is automatic, sharp, and the results are always the same.

This means no mistakes, no loose wires, and there are no weak spots. Every crimp is strong and ready to last.

High efficiency and accuracy features

This combined crimping machine is filled with smart features.

This uses Saro Motors and Sensors to ensure that every crimp is correct. If a wire is missing or not kept right, the machine stops and warns.

It also has an easy-to-use touch screen control panel. Operators can change settings for different wire sizes or terminals in a few seconds.

The body of the multi-terminal crimping system is very strong, which keeps it stable while working. Low vibration means better accuracy. All these features make the machine both sharp and accurate.

Advantages of using a digital control crimping machine

Using an automatic combined crimping machine has many benefits. It saves time because it works much faster than people. It improves quality because every crimp looks the same.

It also lowers costs. Companies do not need many workers for the same job. One person can manage the machine while it does the hard work.

Most importantly, it makes the process safer. Workers no longer need to handle sharp tools or repeat tiring tasks. The machine does everything in seconds with no mistakes.

Applications Across Automotive, Electronics, Industrial

This combined crimping machine is used in many industries. In cars, wires connect the engine, lights, and sensors. Every wire must be strong and safe.

In electronics, the wires are small and delicate. The Industrial cable processing machine makes sure they are crimped with accuracy.

In factories and heavy machines, wires face heat, vibration, and dust. Strong crimps keep the machines running smoothly without problems.

Even home appliances and solar systems use wire harnesses. From fridges to solar inverters, this machine makes sure every connection is safe and durable.

Productivity Gains with Multi-Terminal Crimping Technology

The biggest benefit of this machine is productivity. Since it can crimp three terminals at the same time, it finishes work much faster.

It can process thousands of wires per hour. This is something that manual workers can never match.

The machine also has fewer errors. If something goes wrong, sensors detect it quickly. This saves both time and materials. With such speed and accuracy, companies can meet deadlines and grow their business faster.

Installation, Operation, and Maintenance Made Simple

Many people think advanced combined crimping machines are hard to use, but this one is simple. It is easy to install and comes with a clear guide.

The control panel is friendly, and workers can learn to use it quickly. Changing wire sizes or terminals only takes a few minutes.

Maintenance is also easy. Regular cleaning and small checkups are enough to keep it running for years. If a problem happens, the dual-wire crimping technology shows a clear error message. This makes it easy to fix.

Consider When Choosing the Best Crimping Machine

Not every crimping machine is the same.

Before buying one, think about your needs. Do you need high production speed? Do you use many wire sizes? Do you need very high accuracy?

A good terminal insertion and crimping unit should handle many types of wires and terminals. It should also have sensors to detect errors. A strong design, easy controls, and simple maintenance are also very important.

Always choose a good supplier. The right company will not only give you a good machine, but will also provide support, spare parts and training.

Reliable supplier for High-speed wire harness crimping

When it comes to wire processing, it is very important to choose the right supplier. A good supplier provides advanced machines, reliable quality and post-sales service.

Kunshan Weijiang Company is one of the most reliable manufacturers in the region. They design and manufacture high-performance wire processing and harness assembly machines. Their machines are faster, accurate and manufactured to last.

They also provide full solutions from installation to training and after-sales service. Many industries, such as automotive, electronics, and home appliances, rely on Kunshan Weijiang for their wire processing requirements. If you want a reliable and efficient crimping machine, they are the best option.

Final thoughts

An automatic three-terminal combined crimping machine is a modern solution for wire processing. It is sharp, accurate and easy to use. It saves time, reduces costs, and makes each wire connection strong and safe.

From cars to electronics and even home appliances, it plays a big role in running the machine industries smoothly. Companies that want to stay ahead should invest in automation.

With a reliable supplier like Kunshan Company can get reliable machines and full support. This is the future of wire harness production, where every component is made with high efficiency and accuracy.

FAQs

What is an automatic three-terminal combined crimping machine?

It is a smart machine that covers three terminals at once, making wire processing faster, easier and more accurate.

This machine is most commonly used?

It is widely used in motor vehicles, electronics and industrial areas where many wires require safe and accurate connections.

What are the main benefits of using this machine?

It saves time, reduces errors, increases productivity, and ensures strong and reliable wire connections.

Who is a reliable supplier of these machines?

Kunshan Weijiang Company is a reliable manufacturer that provides high-quality wire processing and harness assembly machines.