In today’s world, industries move fast. To keep up, they need tools that save time and work better. One tool that helps a lot is the smart tape winding machine. This machine is made to wrap tape around wires, cables, and coils neatly and quickly. It’s a big help in wire harness making, electronics, and electrical work.

Smart wire harness tape wrapping machine doesn’t just wrap faster. They also do it better. They offer even wrapping, better control, and less waste. If you need clean and strong insulation, these machines are your best choice. We’ll explain how they work, why they matter, and how to pick the right one for your needs.

High-Precision Tape Winding Machines – Fast, Accurate

When you need clean, tight, and even wraps, an electric tape wrapping machine is the perfect solution. These machines are designed to work fast while keeping every wrap accurate and consistent. They save time and improve the quality of wire harness production. That’s why they are trusted by many industries today.

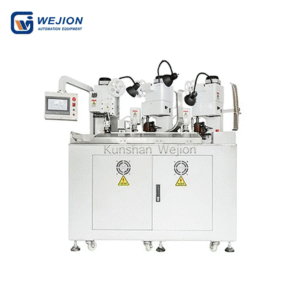

Wire harness tape winding machine

The TW-Z55A tape winding machine is a great choice for wrapping wires, cables, and components. It handles wire harnesses from Φ5mm to Φ55mm. Its strong, compact design makes it easy to use on a desktop. With precise tape placement and smooth movement, this machine wraps each wire neatly and without wrinkles. It’s ideal for small to medium-scale jobs.

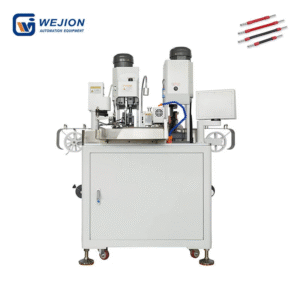

Automatic tape winding machine

On the other hand, the TW-808H automatic tape winding machine is made for larger tasks. It supports continuous winding and works well with different types of tape, like flannel, acetate, and electrical tape. It wraps wires up to Φ40mm and allows you to set the tape size freely. This means you get full control over the finish.

What Is a Smart Tape Winding Machine?

A smart tape winding machine gadget is a high-tech device that wraps tape around items like wires, cables, or coils. The aim is to smarten them neatly and tightly, generally for insulation, labelling, or protection. These machines are plenty better than doing the job by hand.

They have sensors and vehicles that manipulate the tape’s function, speed, and tension. This way, every wrap is easy and proper. Some machines can even remember the quantity of wraps or prevent it while the process is being done. They are regularly used in factories that make cord harnesses for vehicles, electronics, and domestic home equipment.

Unlike older guide machines, smart winding machines can research and modify. That’s what makes them “smart.” They can store settings, exchange speeds, and wrap different objects readily. This saves time, lowers errors, and boosts fines.

Features That Make It Ideal for Wire and Cable Wrapping

Smart tape winding machines come with functions that make them perfect for wrapping wires and cables.

- They provide high-speed wrapping. This means you can wrap more in less time. That’s super for busy production traces. Even higher, they do that with high accuracy, ensuring that every wrap is smooth and tight.

- Another feature is the adjustable tape tension. Tension is crucial because it impacts how well the tape sticks. If it is too tight, the wire could bend or break. If it is too loose, the tape may fall off. Smart machines fix this by means of adjusting the tension simply properly.

- Many machines also have touch screen controls. These are easy to use and help workers choose the right settings for different jobs. Some even save these settings, so you don’t have to enter them again.

- Automatic tape winding equipment also comes with auto-stop and alarm systems. These stop the machine if something goes wrong, like if the tape runs out or breaks. This keeps the machine and your work safe.

- Many of these machines are built for multi-angle wrapping. This is important when wrapping parts of different shapes. Whether it’s a round wire or a flat cable, the machine wraps it smoothly.

Benefits of Using Smart Tape Winding Machines

Using smart tape winding machines brings many benefits to your work. One of the biggest is speed. These machines wrap much faster than any person can. This helps you finish big jobs quicker and meet deadlines with ease.

Next is quality. Smart machines make sure every wrap looks the same. This makes your products look more professional and reduces the chance of problems later. Bad wrapping can lead to short circuits, weak insulation, or loose ends. With smart machines, those risks go away.

Another benefit is less waste. Because the machine controls how much tape to use, you only use what’s needed. This saves tape and lowers your costs. Over time, these savings can be big.

Smart winding machines also reduce fatigue for workers. Manual tape wrapping takes time and effort. It can hurt hands and arms after many hours. Smart machines do the hard work, so workers stay fresh and safe.

Using a smart cable wrapping machine improves production planning. Since the device works at a hard and fast velocity, you may be wondering how long every job will take. This enables plan better and supply on time.

How Smart Winding Technology Improves Precision and Speed

Adhesive tape winding system uses advanced structures to enhance each velocity and precision. It starts with the servo motor, which controls how the tape moves. This motor responds speedily and as it should be, supporting the gadget live on the right track.

Many machines also use position sensors. These checks were where the wire or cable is, so the tape lands in the right spot every time. The sensors send signals to the machine to adjust in real time. This keeps the wrapping smooth, even if the shape changes a little.

Some smart machines also have programmable logic controllers (PLCs). These small computers let you enter detailed instructions like speed, tape angle, and wrap length. Once you program it, the machine follows the plan perfectly. That means no gaps, no overlaps, and no rework.

Because everything is automated, the machine can work faster without making mistakes. You get high speed and high quality together. That’s a big win for any factory or workshop. It also means you can take on bigger jobs and still deliver great results.

Choosing the Right Tape Winding Machine for Your Needs

Choosing the right smart coil tape winding solution depends on your work. Start by thinking about what you’ll wrap. Are they small wires, big cables, or complicated coils? Some machines take care of skinny wires better, while others are made for thicker cables.

Consider the tape width and type. Not all machines work with each type of tape. Make certain the gadget you pick out can cope with your preferred tape—whether or not it’s PVC, material, or foil tape.

Test the wrapping pace. If you’ve got large orders, move to a high-velocity version. But if you attention on fine or small batches, a slower, greater specialised gadget is probably better.

Don’t neglect the controls. A proper gadget needs to be clean to use. Look for one with a clean display, reminiscence settings, and mistake indicators. These functions save time and help new users study quickly.

Think about the area and setup. Some machines are small and fit on a table. Others are bigger and need ground space. Choose what suits your store or manufacturing unit.

Trusted Industry Leader in Wire Harness Processing Equipment

When it comes to smart tape winding machines and wire harness equipment, one name stands out—Kunshan Weijiang Automation Equipment Co., Ltd. This company is a trusted leader in the field. They are known for offering complete wire processing and harness assembly machines and solutions.

Kunshan Weijiang focuses on quality, service, and innovation. They make machines that are strong, smart, and made for long-term use. Their tools are perfect for auto wiring, home electronics, and many other industries.

Their lineup consists of everything from high-speed tape applicators to twine cutting, stripping, and crimping equipment. They help businesses accelerate production, reduce errors, and improve great.

By selecting Kunshan Weijiang, you get more than a machine. You get assistance, training, and peace of mind. They are the benchmark manufacturing unit in this space, depended on by way of brands internationally.