Factories today need work that is fast and clean. Every factory wants a smooth flow. Every factory wants less waste. A professional touch screen wire cutter supplier helps achieve this goal. These touch screen wire cutter supplier offer strong machines. These machines cut wires with care. They help reduce errors. They help save time each day. They also help protect workers during daily tasks. When work becomes easier, production grows. When production grows, business becomes stronger. Many factories now use an Industrial wire stripping machine with touch screen for daily work. This type of machine features a single clear screen. All settings stay in one place.

Smart Cable Processing for Modern Lines

Touch control ensures the cable works smoothly and quietly. There are no hard keys. There are no complex panels. A CNC wire cutting machine with HMI shows clear options on the screen. Each step is easy to read. Each step is easy to choose. Workers can save jobs. They can load old jobs again. This saves setup time and also ensures that quality remains consistent every day.

A touch screen programmable wire stripper gives gentle control. It cuts the wire clean. It strips covers with care. It works well with thin wire. It also works with a thick cable. One machine supports many tasks. This helps factories avoid buying many tools. Space is saved. The cost is lowered. Work becomes more flexible and straightforward.

Fully Automatic Wire Cutting Solutions

Automation helps factories work without delay. It allows large plants to work quickly. It helps small shops too. A trusted high speed wire cutting machine manufacturer builds machines for extended use. These machines can run all day. They can run all night. They keep the speed steady. They keep cuts accurate. Workers can focus on other tasks while machines work.

Many buyers ask about the automatic cable cutting and stripping machine price before purchase. The price depends on cable size. It depends on the machine speed. It also depends on the type of control. Even if the price seems high at first, the value is clear later. Automatic machines reduce waste. They reduce labor costs. Over time, they save much more money.

Recommended Heavy-Duty Cable Cutters

- C-C240 Pneumatic Heavy-Duty Cable Cutter

The C-C240 is designed for demanding tasks. It cuts cables up to 240mm² with ease. It uses air power to drive the blade. This makes each cut smooth. This makes each cut safe. The operator feels less strain. The tool stays stable during work. This cutter fits power plants well. It also fits heavy cable lines in large factories. It is strong and most reliable.

- C-C50 Pneumatic Large Size Cable Cutting Machine

The C-C50 is designed for use with large cables. It handles thick wire without stress. The body is solid. The cutting force is strong. Each cut stays clean and even. This machine works well with copper cable. It also works well with aluminum cable. It suits factories that handle large quantities of wire daily. It keeps output stable. It keeps quality high.

- CS-3030Q Wire Cutting Machine Cable Cutting Machine

The CS-3030Q is designed for speed and accuracy. It works fast without losing control. It suits medium cable tasks. The screen is clear and bright. The setup steps are short. Workers can finish the setup in minutes. Daily use feels easy. This machine is ideal for factories that require steady daily output with minimal effort.

- CS-8150Q Fully Automatic Large Cable Cutting Machine

The CS-8150Q is built for very heavy work. It supports cable rolls up to 150kg. It runs entirely automatically from start to end. Manual handling is reduced. Worker safety is improved. This machine is suitable for large plants and busy lines. It saves many hours of labor each week. It also keeps cutting results stable for long runs.

Multi-Function Wire Processing Equipment

A computerized touch screen wire cutter supplier typically offers multi-purpose machines. These machines do more than one job. Many can cut wire. Many can strip covers. Some can crimp terminals, too. This reduces the need for many machines. It also saves factory space. Workflows become shorter and cleaner.

An automatic terminal crimping and stripping machine improves joint quality. Each crimp stays tight. Each strip stays clean. The result remains the same every time. Human error is reduced. Product quality becomes stable. This is crucial for ensuring electrical safety and prolonging product life.

Special Machines for High Precision Work

An automatic 16 wheel wire peeling machine holds the wire gently. The wheels adjust pressure evenly. The jacket is removed without damage. Inner cores stay safe. This is ideal for soft wire. It is also suitable for long cable runs. Precision remains high from the first piece to the last.

The SWT508MAX1 touch screen wire cutter supplier focuses on fine control. This model suits small and medium wires. Speed stays high. Size stays exact. Edges stay smooth. This helps factories that require clean aesthetics and precise size control. It supports quality-focused production lines.

Touch Control Makes Work Easy

Touch control cable processing equipment is easy for all age groups. Young workers learn quickly. Older workers feel confident. The screen uses clear icons. The steps are simple. The text is easy to read. Training time becomes short. Daily work feels lighter and safer.

With touch control, fewer errors happen. Settings stay saved. Jobs repeat with the same result. This builds trust in the process. Workers feel less stress. Managers see better output numbers.

Key Benefits of Choosing a Professional Supplier

- Strong and stable machine quality

- Simple and precise touch screen control

- Fast support after purchase

- Many machine options for all needs

- Long working life with low repair cost

Compare the Touch Screen Wire Cutters

| Machine Model | Cable Size | Operation Type | Best Use |

| C-C240 | Up to 240mm² | Pneumatic | Heavy cable cutting |

| C-C50 | Large size | Pneumatic | Thick cable work |

| CS-3030Q | Medium cable | Automatic | Daily factory use |

| CS-8150Q | Up to 150kg | Fully automatic | Large scale plants |

Buy from Reliable Touch Screen Wire Cutter Supplier

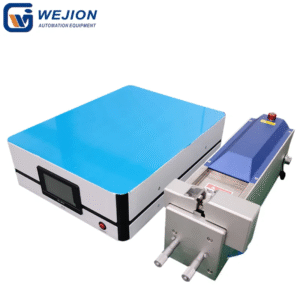

Kunshan Weijiang Automation Equipment Co., Ltd. is a trusted global brand touch screen wire cutter supplier. The company designs strong machines. They test them carefully and support customers after-sales. Clear guides are shared and spare parts are available. Help is easy to reach. The company’s website provides detailed product information. As a top touch screen wire cutter supplier they show real machine photos. Buyers can compare models easily. This openness builds trust. Many factories choose this brand for long-term use.

A professional touch screen wire cutter supplier supports factory growth. Intelligent machines bring smooth work. Easy control saves time. Strong models give long service. With the right machines, production becomes stable, safe, and ready for the future.

FAQs

- What is a touch screen wire cutter?

It is a cutting machine with a screen. The screen controls all steps. The user touches the screen to set jobs.

- Are automatic machines safe?

Yes. Automatic machines reduce hand contact. The cutting area stays closed. Risk becomes lower. Safety becomes higher for daily work.

- Can one machine cut many wire types?

Yes. Many machines support different wire sizes. Settings can be saved. Jobs can be changed quickly. This adds flexibility to production.

- Where can I find reliable machines?

Kunshan Weijiang Automation Equipment Co., Ltd. provides trusted machines. Their website shows full details and support options.