The PC – RB50 rotary – knife dust – free pipe cutting machine specializes in processing 50 – 100mm diameter pipes. Its advanced dust – control technology keeps the working environment clean, eliminating dust hazards. With precise rotary – knife cutting, it ensures smooth, accurate cuts for various materials.

The PC-RB50 dust-free rotary knife pipe cutter is an efficient and environmentally friendly pipe cutting equipment designed to solve the dust and waste problems generated during the pipe cutting process. Its main feature is that through its unique structure and technology, it avoids the dust and metal or plastic chips commonly generated by cutting in traditional pipe cutting methods, thereby providing a cleaner and safer working environment.

Functions & Features:

1. Dust-free cutting

* Built-in dust suction system: The dust-free rotary knife pipe cutter is equipped with an efficient dust suction device, which can suck away the dust and waste generated in real time during the cutting process to keep the working area clean. Usually the dust suction system uses a powerful fan and a filtration system to efficiently capture and clean the metal chips, plastic dust, etc. generated during the cutting process.

* Reduce pollution: The system effectively reduces the waste chips and dust generated during the cutting process, avoiding pollution of the air, equipment and operators. It is particularly suitable for industries that need to maintain a clean environment, such as electronic manufacturing, medical treatment, food processing, etc.

2. Precision cutting

* Rotary knife cutting: Cutting with a high-speed rotary knife can provide very precise cutting results, and the cutting surface is smooth, flat and burr-free. The rotary knife can reduce the high temperature caused by friction in the traditional cutting method, avoid thermal deformation or coking, and ensure the cutting quality of the pipe.

* Efficient processing of hard pipes: Rotary knives are particularly suitable for cutting hard pipes (such as metal pipes, stainless steel pipes, plastic pipes, etc.), and can quickly complete high-precision cutting tasks to adapt to different pipes and cutting requirements.

3. Environmentally friendly design

* Reduce working environment pollution: Traditional pipe cutting machines often produce a lot of dust and waste chips during the cutting process, which not only pollutes the environment, but also threatens the health of operators. The dust-free rotary knife pipe cutting machine greatly reduces environmental pollution through effective waste chip absorption and filtration technology, which meets the environmental protection requirements of modern industry.

* Low noise design: Compared with traditional cutting methods, dust-free rotary knife pipe cutting machines are usually designed with low noise characteristics, which reduces noise pollution and is suitable for production lines that need to maintain a quiet environment.

4. High cutting efficiency

* High-speed rotary knife: The dust-free rotary knife pipe cutting machine uses high-speed rotary knives to cut, with fast and stable cutting speed, and can quickly complete the cutting task of large quantities of pipes. Compared with traditional sawing or band saw cutting, the cutting efficiency of rotary cutters is significantly improved, and the production cycle is reduced.

*Automated operation: The equipment is usually equipped with an automated control system, which supports fixed-length cutting, automatic feeding and automatic material withdrawal. It is easy to operate and can complete production tasks efficiently.

5. High precision and smooth cutting surface

*Precise cutting: Rotary cutters can ensure high cutting accuracy and smooth and burr-free cutting surfaces during cutting. This is especially important for industries that require strict tolerances (such as automobiles, electronics, aviation, etc.), avoiding unqualified pipe ends during the cutting process.

*High-quality cutting surface: The cutting surface of rotary cutters is usually smoother than traditional cutting methods, reducing the workload of subsequent processing and cleaning.

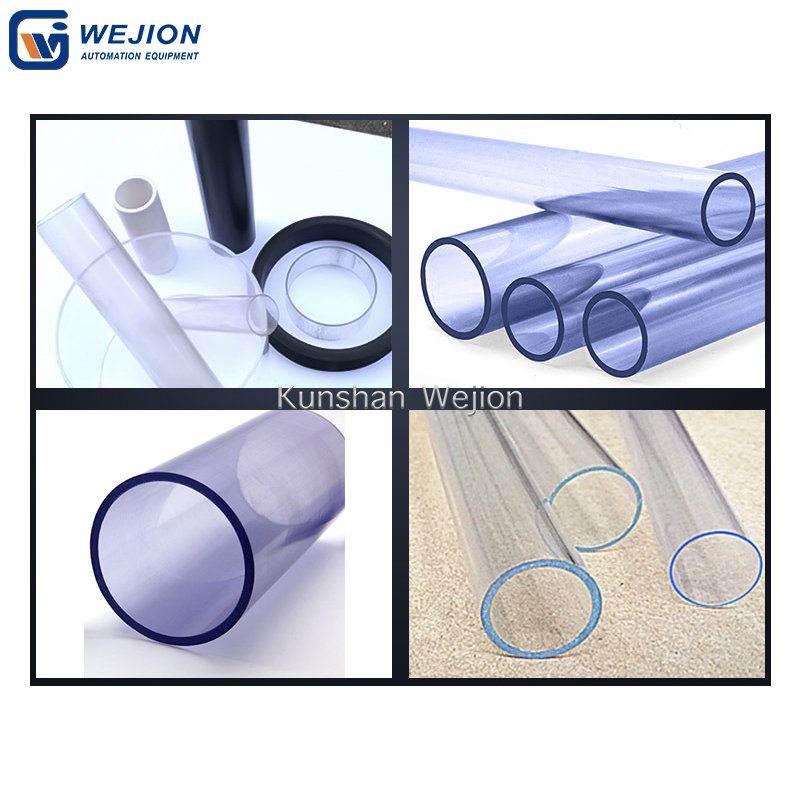

6. Wide range of pipe types

*Multiple pipe cutting: Dust-free rotary cutter pipe cutting machines are suitable for cutting a variety of pipes, including metal pipes (such as stainless steel pipes, aluminum pipes, copper pipes, etc.), plastic pipes (such as PVC, PE, PPR pipes, etc.), composite pipes, etc. Regardless of the hardness, thickness or material of the pipe, the rotary cutter can provide efficient and precise cutting results.

* High flexibility: The design of the equipment enables it to adapt to different sizes and shapes of pipes, and is suitable for pipe processing needs in a variety of industrial fields. .

7. Simple operation and high safety

* Intelligent control: The dust-free rotary knife pipe cutting machine is equipped with a modern PLC control system with an intuitive control interface. Users can easily set cutting parameters (such as cutting length, speed, etc.) through the touch screen. At the same time, the equipment runs stably, and the operator only needs simple training to operate proficiently.

* Safety protection device: The equipment is usually equipped with multiple safety protection measures, such as emergency stop buttons, protective covers, safety gratings, etc., to ensure the safety of operators.

9. Reduce operating costs

* Reduce cleaning costs: Due to the efficient dust collection system of the dust-free rotary knife pipe cutting machine, the dust and waste generated during the production process can be cleaned up in time, reducing the cleaning workload and labor costs.

* Reduce health risks: Reduce dust exposure and waste diffusion, avoid the negative impact on the health of operators due to long-term exposure to dust environments, thereby reducing health risks and medical costs.

| Model | PC-RB50/100 |

| Voltage | 220V/360V |

| Power | 450W |

| Weight | 200KG |

| Speed | Automatic speed, infinitely variable |

| Maximum pipe diameter | 100mm |

| Cutting length | 3-1000mm(Or longer) |

| Machine size | 155*107*67cm |

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to wj3@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions