CS-M300 automates variable-length multi-core wire processing, eliminating inefficient manual cutting, stripping and insulation tasks. This intelligent system delivers precise, consistent results with one-touch operation while reducing labor costs and workplace risks – the optimal solution for modern wire production.

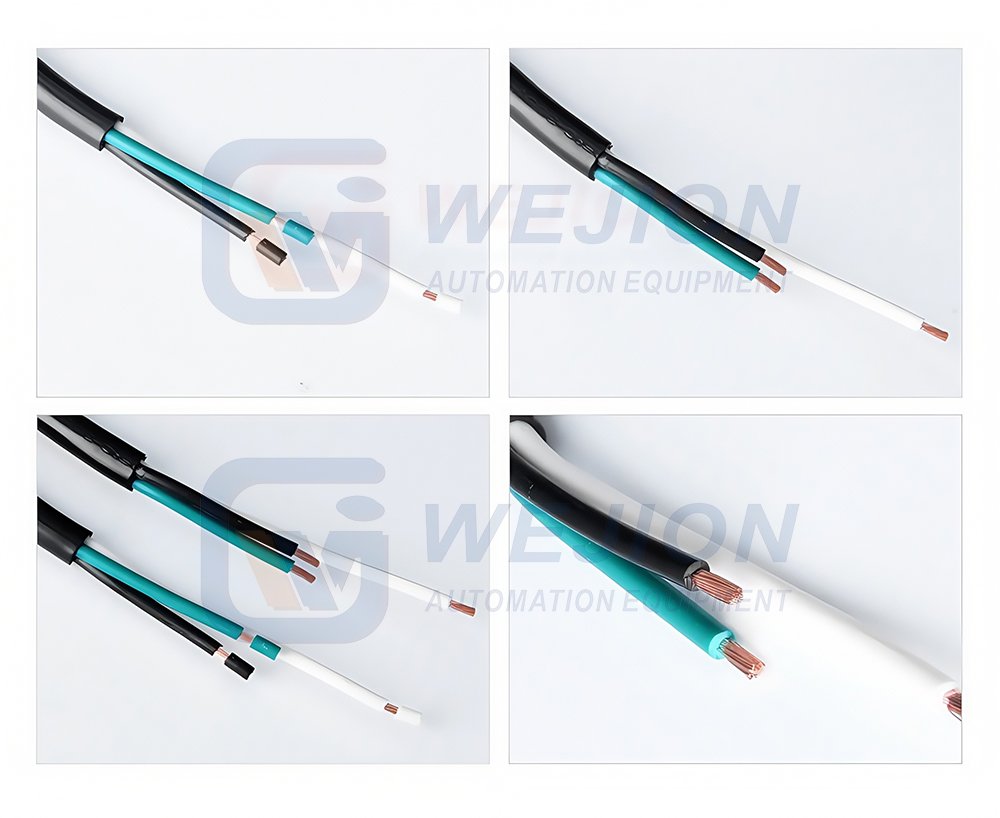

CS-M300 multi-core wire cutting and stripping automatic machine is an automated equipment that is very suitable for processing various types of multi-core cables. It has the characteristics of high efficiency, strong stability, and adjustable structural design. It can not only solve the problems of inefficiency and error-proneness of traditional manual operation, but also greatly improve the work efficiency of the production line, reduce the labor intensity of employees, and improve production safety. Whether it is power cable, automotive wiring harness, electronic cable, or new energy industry, it can ensure high-quality and high-efficiency production with the support of this equipment.

Function & Features

1. Ergonomic design

* The oblique back design is ergonomic, reduces the labor intensity of operators, makes operation more comfortable, and reduces fatigue during long-term use.

2. Servo motor control

* The servo motor control ensures the precise adjustment of the wire cutting length, more precise operation, reduces manual errors, and improves production efficiency.

* The computer can adjust the length of the wire. Users can easily set the required cutting length through the operation interface and flexibly respond to different production needs.

3. Adjustable structure design

*Adjustable structure, the structure of the equipment can be adjusted according to the thickness of the wire and processing requirements, adapting to the processing of wires of different specifications and types, greatly improving the versatility of the equipment.

*Flexible adjustment of the structure ensures that various types of multi-core wires can be processed while ensuring processing quality.

4. Simple structure, easy to adjust

*The equipment has a simple structure and convenient settings and adjustments, which reduces the complexity of operation, facilitates quick adjustment and reduces downtime.

*The operation interface is intuitive and easy to understand, and even novices can quickly master the operation method of the equipment.

5. High efficiency and strong stability

*The high efficiency of the equipment makes the production process smoother, and can complete the processing of a large number of multi-core wires in a short time, greatly improving production efficiency.

*Stable performance, after precise adjustment, the equipment can run stably for a long time, reducing equipment failures and downtime.

Application areas

1. Wire and cable industry

*Suitable for cutting and stripping of various multi-core wires and cables, especially on production lines that need to process multiple cores at the same time.

*The processing of power cables, communication cables, control cables, etc. can be completed efficiently.

2. Automotive wiring harness manufacturing

* In the production of automotive wiring harnesses, CS-M300 can handle operations such as cutting, stripping, and splitting of multi-core wires, adapting to the high-efficiency production needs of the automotive industry.

* Suitable for various automotive electrical circuits, such as sensor harnesses, control harnesses, battery harnesses, etc.

3. Electronic manufacturing industry

* Suitable for the production of multi-core cables involved in electronic products, such as power cords, signal cords, and connecting cords of various equipment.

* Can accurately process electronic cables of various sizes and specifications.

4. New energy industry

* Especially suitable for the processing of new energy cables, such as cables for electric vehicles, charging piles, solar power generation systems, etc.

* Adapt to the needs of large-size cable stripping and cutting, and can handle thicker wires and high-current cables.

5. Home appliance industry

* In home appliance production, CS-M300 can efficiently process various home appliance cables, including power cords, signal cords, connecting cords, etc., to ensure efficient connection and safety of electrical equipment.

6. Communications industry

* Suitable for the processing of communication cables to ensure efficient transmission and stable connection of cables.

*Can be applied to the processing of network cables, optical fiber cables, etc., to meet various high-precision stripping and shearing requirements.

7. Industrial Automation and Robotics

*Suitable for cable processing of various industrial automation equipment and robot harnesses. Ensure that the equipment can stably transmit power and signals in high-speed and precise operations.

| Model | CS-M300 |

| stripping section | 4 sections (can strip 4 different size section) |

| Stripping length | 5-15mm |

| Cutting length | 25-290mm |

| Cutting core range | 0.5-3mm² |

| Function | Cutting and stripping wires of different lengths |

| Storage capacity | 99 kinds of processing parameter data |

| Display method | Touch screen |

| Power supply | AC220V 50HZ |

| Power | 500W |

| Weight | 110kg |

| Dimension | 900*500*1360mm |

Wire Harness Production: Used to strip insulation from multi-core cables of different lengths for automotive wiring harnesses, ensuring proper connections in ECUs, sensors, lighting systems, and infotainment systems.

EV Battery Wiring: Essential for processing high-voltage cables in electric vehicles (EVs), where precision stripping is critical for safety and performance.

Consumer Electronics: Strips wires in devices like smartphones, laptops, and tablets, where multi-core cables (e.g., USB, HDMI, FPC) require different stripping lengths.

Home Appliances: Used in washing machines, refrigerators, and air conditioners for internal wiring with varying core configurations.

Control Panel Wiring: Processes multi-core control cables for PLCs, servo motors, and sensors, ensuring accurate stripping for reliable signal transmission.

Robotic Arm Cabling: Handles flexible multi-core wires in robotic systems, where different lengths are needed for movement and connectivity.

Avionics Systems: Strips shielded multi-core cables for flight control systems, communication devices, and navigation equipment, meeting stringent safety standards.

Military-grade Wiring: Ensures precision in armored vehicle and radar system cables, where durability and accuracy are crucial.

Diagnostic Devices: Processes fine multi-core wires in MRI machines, ultrasound systems, and patient monitors, requiring high precision to avoid signal interference.

Surgical Tools: Used in robotic surgery equipment and endoscopic devices, where small-diameter, multi-core cables need consistent stripping.

Fiber Optic & Network Cables: Strips multi-core Ethernet and fiber optic cables for routers, servers, and patch panels, ensuring high-speed data transmission.

5G Infrastructure: Supports the production of antenna and base station wiring with varying core lengths.

Solar Panel Wiring: Processes multi-core photovoltaic cables with different stripping lengths for junction boxes and inverters.

Wind Turbine Cabling: Handles thick, multi-core power and control cables inside turbine nacelles.

Prototype & Small-Batch Production: Ideal for R&D labs and custom cable manufacturers that deal with non-standard wire lengths and configurations.

✔ High Precision: Ensures clean cuts without damaging conductors.

✔ Flexibility: Adjustable settings for different wire gauges and insulation types.

✔ Efficiency: Reduces manual labor and increases production speed.

✔ Consistency: Maintains uniform stripping quality across batches.

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to wj3@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions