In today’s world, industries require strong, safe and accurate equipment to handle their daily tasks. One such device is a pneumatic cable cutter. It is designed to cut thick cables, wires and harnesses easily. Unlike manual cutters, this device uses compressed air to give powerful and accurate cuts. It makes rapid, safe and more reliable for factories, workshops and production lines.

Working Principle of the Pneumatic Cable Cutter

The function theory of a pneumatic cable cutter is still powerful. It uses compressed air as the main source of energy. When the operator presses the trigger, the air pressure runs a piston or cylinder inside the tool. This force carries the sharp cutting blade that slices quickly and cleanly through the cable.

Unlike manual cutters, where the operator should use muscle strength, pneumatic cutters rely on air pressure. This makes the work easier and sharper. Even thick and strict cables can be cut without much effort. The air-powered system also ensures a continuous force of cutting force, which reduces mistakes and improves security.

Industrial pneumatic wire cutters also come with security locks and control systems. These features prevent accidents and allow operators to control cutting speed and force. In this way, the cutter provides both power and precision in a package.

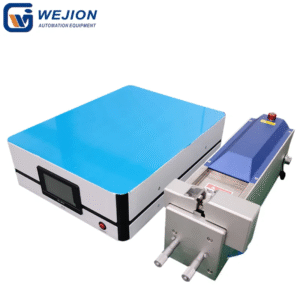

High-Performance Pneumatic Cable Cutter – (C-C240)

The C-C240 pneumatic heavy-duty is designed for cable cutter strength, speed and accuracy. It is designed to handle cables up to 240 mm, including thick insulation and armoured layers. This creates a reliable option for industries that demand accurate and safe cable processing.

Work -power

C-C240 uses a strong pneumatic drive that provides consistent strength. With compressed air, the cutter slices smoothly through large wires without extra effort. This ensures clean cuts that reduce the competing and improve the quality of the cable connection.

key features

This heavy-duty pneumatic cutter is safe, simple and sharp to operate. Its manual solenoid valve design makes it reliable and easy to control. It can handle the size of the cable from 1 mm to 160 mm, giving it a broad versatility. Users can also retrofit the machine with a pedal, converting it into an electric option for even more convenience.

Industrial benefits

With low gas consumption and low failure rate, C-C240 saves both time and cost. Its easy maintenance design means low downtime in production. For factories, workshops and wire processing plants, this pneumatic cutter is a reliable device that distributes long -lasting performance.

Top features of pneumatic cable cutters

A premium pneumatic cable cutter comes with the characteristics that make it stand out.

One of the main characteristics is durability. These cutters are made with high-quality steel and alloys that can withstand daily use in a rigid environment. They do not easily wear out and can live for years.

Another feature is accurate cutting. Fast blades are designed to give smooth and clean cuts without damaging the cable. This is very important in industries such as electrical and motor vehicles, where even a small mistake can cause major problems.

Speed is also an important feature. With compressed air, these cutters can cut cables much faster than manual tools. It saves time and increases productivity. Heavy-duty pneumatic cable cutting machines are designed to be mild and easy to handle. Operators can use them for a long time without getting tired.

Benefits of Using a Pneumatic Cable Cutter

The benefits of a pneumatic cable cutter go beyond simple cutting.

- One of the biggest benefits is efficiency. Since the tool uses air pressure, it can cut through thick cables in seconds. It reduces the working time and improves the speed of production.

- Another benefit is security. Manual cutters often require power and cause accidents or injuries. Pneumatic cutters reduce this risk by providing smooth, controlled cuts. Operators can focus on work without emphasising hands or weapons.

- Stability is also an advantage. Premium pneumatic cutters are made with strong materials to withstand wear and tear. They can handle continuous use without damage, which reduces maintenance costs.

- The accuracy is another strong point. The cutter creates clean cuts that protect the integrity of cables. This is especially useful in industries where cables are used for electrical connections, as poor cuts can cause errors.

- Compressed air cable cutters are versatile. They can be used in many industries, from motor vehicles to telecommunications. This makes them a valuable investment for any company.

Applications in Industrial Uses

Pneumatic cable cutters are used in many industries because of their strength and accuracy. In the motor vehicle industry, they are used to cut wires and seals for vehicles. Using a pneumatic wire and harness cutter, manufacturers can prepare the wiring system quickly and with accuracy.

In the electrical industry, these cutters are used to cut electric cables, control lines and other conductors. A clean and accurate cut ensures safe electrical connections and prevents errors.

The telecommunications industry also depends on pneumatic cutters. Cables used for data and communication should be carefully handled. These cutters ensure that cables are not damaged while cutting.

Production systems and construction sites often use pneumatic cutters to handle heavy cables. They are also useful in aviation and shipbuilding, where strong and reliable wiring systems are required.

Due to the wide range of applications, pneumatic cutters have become a tool for industries that require accuracy and security.

Materials Used for Pneumatic Cable Cutter Manufacturing

The durability and performance of pneumatic cable cuts depend on the materials used.

Most premium cutters are made of the best steel or alloy steel. This makes them strong enough to meet pressure and heavy use.

Cutting leaves are usually made of hard steel or tungsten carbide. These materials are very fast and resistant to wear. They make sure the cutter makes smooth cuts without losing quickly.

The cutter’s body can be made from aluminium alloys to keep the tool easy to use. At the same time, these alloys are strong enough to oppose the effect and rough handling.

Other ingredients, such as rubber or plastic composites, are used for handles. These provide comfort and grip, making it easier to operate the device. Some cutters also include anti-slip coatings to improve safety.

Using premium content, manufacturers ensure that pneumatic cable cutters remain reliable and effective even in a difficult industrial environment.

Why choose a durable and exact cutting tool?

Choosing a durable and accurate air-powered cable cutting tool is very important for industries. A weak or low-quality device can easily break, cause delays, and even give rise to accidents. On the other hand, durable equipment ensures smooth operation and long service life.

Accuracy is equally important. In industries such as automotive and electronics, a poor cut can cause major problems. It can damage cables, reduce efficiency and increase costs. An accurate cutter prevents such issues and ensures clean, safe and accurate cuts each time.

A durable and precise pneumatic cutter also reduces the cost of maintenance. Since it lasts for a long time, companies do not have to change it often. This makes it a cost-effective investment.

Precision pneumatic wire cutter workers help improve safety and productivity. When operators have the right equipment, they can do their work rapidly and with less effort. It leads to better results and smoother production.

Where to Buy the Best Pneumatic Cable Cutter?

When it comes to buying a premium pneumatic cable cutter, it is always best to choose a reliable supplier. One such company is Kunshan Weijiang Automation Equipment Co. They are famous for high-quality wire processing and offering harness assembly machines and solutions.

Kunshan Company focuses on giving durable, safe and efficient equipment to meet the needs of various industries. Their pneumatic cable processing equipment is designed with advanced technology and top-quality materials. It ensures excellent performance, long life and reliable operation.

The company also provides a complete solution for wire processing and harness assembly. This makes them a stop supplier for industries such as motor vehicles, electronics, telecommunications, and more.

Kunshan Weijiang Company, by choosing Limited, companies get more than one tool. They get a partner who understands their needs and provides the best solution to run their production lines smoothly.