The wires are the backbone of modern technology. From cars and electronics to home appliances and communication machines, wires are all connected. But before the wires can be used, they need to be taken away. Stripping means removing the outer coating so that the internal metal core can create a strong connection. It takes time to do this by hand, and it can cause mistakes. This is why factories and workshops now use multifunctional wire stripper machines.

These automatic cable stripping machines make the process easy, faster and reliable. They can handle separate wire shapes and materials, ensuring smooth and accurate stripping each time.

Mechanism of the multifunctional wire stripper machines

The mechanism of a multifunctional wire stripper machine is simple but powerful.

The machine holds wires firmly using rollers or clamps. Then, acute blades cut into insulation without damaging internal metal conductors. Once the insulation is cut, it is pulled away, leaving a clean wire core, designed to be soldered, soldered or used.

Some machines may also bend, cut and collect wires in a cycle. They use precise motors and sensors to ensure each strip is accurate. Operators can set the length, depth and speed of the wire using a simple control room. The entire process occurs automatically, which saves time and reduces errors.

The greatest strength of these machines is their flexibility. They can process a variety of wires, such as copper, aluminium, or coated wires, only with a few adjustments. This makes them highly useful in industries where multiple wire shapes are required.

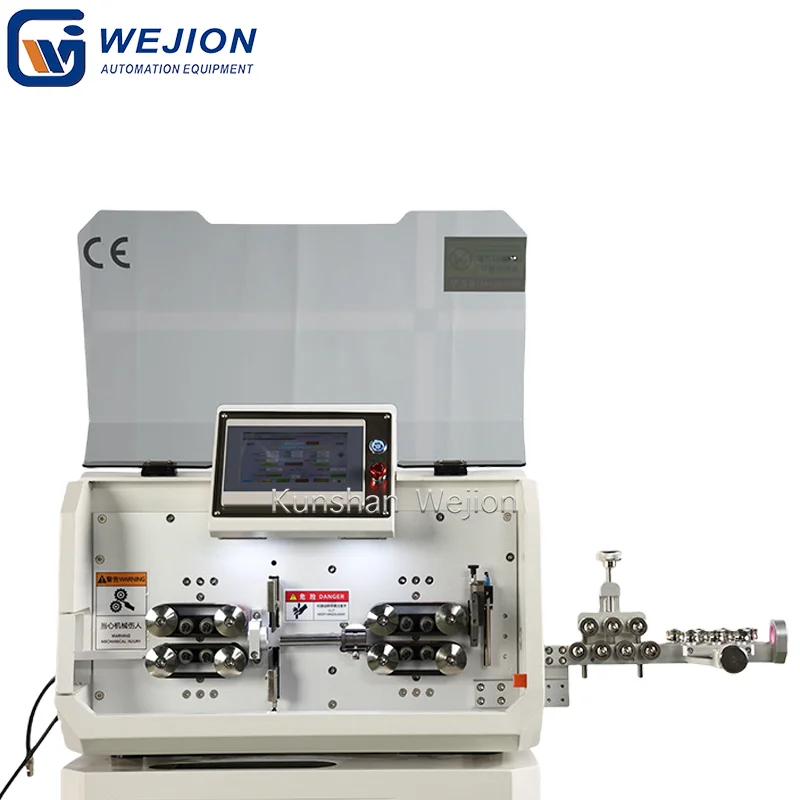

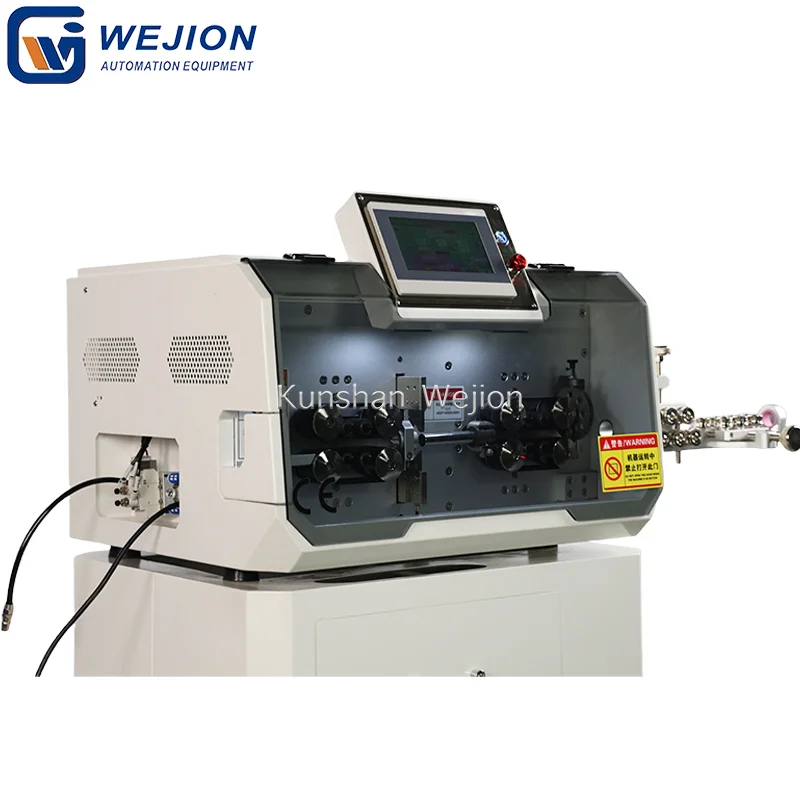

Advanced Multifunctional Wire Stripper Machine-CS-3630

Powerful Wire Processing

The CS-3630 is designed for accuracy and speed for accuracy and speed. It automatically cuts cutting and strips, and makes it ideal for single-core wires, multi-core cable, preserved cable and PVC wires. With its detailed processing range, it can handle cables up to 30 mm, and even cut up to 50 mm when needed.

High efficiency and precision

This large cable wire processing equipment performs full and half stripping at the end of both wires. Its cutting accuracy is very high, which keeps tolerance within 0.002 times the cutting length. With the production capacity of 3,500 pieces per hour, it ensures efficiency while maintaining stable performance.

Smart mechanical design

The CS-3630 uses a 16-wheel drive system with stapper and Saro Motors. Its belt-feeding design protects the cable from scratches or indentation, while adjustable digital pressure wheels ensure simple, stable operation.

Flexible and user-friendly

Adaptability is another major feature. The machine supports alternative functions such as MES and IOT system, coding, middle stripping and external alarm. With your 7-inch colour touchscreen, operators can easily control the settings. Manufactured with modular interfaces, it allows upgradation and adaptation to special production requirements.

Benefits of using a multifunctional wire stripper machine

Using a multifunctional wire stripper machine provides many benefits. The first is speed. Manual stripping is slow and tiring, but a machine can process wires in seconds. This increases productivity and helps companies meet the deadline.

The second advantage is accurate. Human hands can make uneven cuts, but machines ensure that each wire is taken away at the same length and depth. This stability improves the quality of the final product.

Cost savings are another major benefit. By reducing waste and errors, the factory spends less on the material. Since manual stripping requires fewer workers, labour costs also decrease.

These industrial wire cutting and stripping machines also improve safety. Manual stripping requires sharp equipment and causes damage. With an automatic machine, the risk is very low. The machine provides flexibility, as it can treat different thread types and sizes, making it a smart investment for industries with different requirements.

Wire Stripper Machine Materials

The strength and reliability of a multifunctional wire stripper machine depend on the materials used in its manufacture.

High-grade steel is often used for frames and internal moving parts. The steel machine gives the ability to handle high-pressure stripping without bending or breaking.

The blade is usually made of hard alloy steel or tungsten carbide. These materials are strong enough to cut through hard insulation without tearing out quickly. Using quality blades ensures smooth stripping and reduces downtime for the replacement of the blade.

For electronic parts, industrial-quality plastic and aluminium alloys are used. This material keeps the machine light but strong. The wires and connectors inside the machine are made of copper for better conductivity and reliable performance.

This material creates a machine that is stable, long-lasting, and able to handle continuous use in factories.

Industries That Use Multifunctional Wire Stripper Machines

Multifunctional wire stripper machines are used in many industries. In the automotive industry, they are required to make power lights, engines and sensors, and a wiring harness. Each vehicle has hundreds of wires, and machines ensure that each is ready with accuracy.

In the electronics industry, these precision wire stripping tools prepare wires for gadgets, equipment and circuit boards. A clean and accurate strip ensures that the device works safely and smoothly.

The telecom industry also depends on them. With thousands of cables required for data and voice connections, machines help to create coherent and reliable wiring.

In aerospace and medical equipment construction, accuracy is also more important. Here, machines ensure that strict standards for the safety and performance of wires are met.

Choose the Best Multifunctional Wire Stripper Machine

Choosing the right multi-core cable stripper system depends on your needs.

- The first thing to investigate is the wire range. Ensure that the machine can handle the size and types of use of your factory.

- Think about the speed of production. If you need thousands of wires daily, go for a high-speed model. The accuracy is another important point. A machine with advanced sensors and accurate blades will give better results.

- Ease of use should not be ignored. See for simple touchscreen and user-friendly control models. Stability is also important. Machines manufactured with strong materials last longer and require less maintenance.

- Consider the post -sales support support. A good supplier will offer training, spare parts and quick service if necessary. This ensures smooth operation and reduces downtime in your production line.

Industry Leader for Automatic Wire Harness Processing Equipment

When it comes to reliable suppliers, the Kunshan Weijiang Automation Equipment Co., Ltd. stands out. The company is a pioneer in wire processing and harness assembly machines, and solutions. They focus on high-quality shielded cable stripping machines that combine innovation, speed and reliability.

Kunshan Weijiang has provided high-speed wire processing solutions, including wire cutting, stripping, crimping and harness assembly systems. Their equipment is designed to meet the needs of various industries, from motor vehicles and electronics to telecommunications and equipment.

What makes them special is their strong customer service. They not only provide machines, but also provide training and complete solutions for smooth production. With your experience and reputation, Kunshan Weijiang is the right choice for businesses looking to promote wire processing efficiency.