In today’s fast-paced industrial world, efficiency and precision are more important than ever. From automotive to electronics and telecommunications, wires and cables are necessary in almost every industry. Manually handling these wires can be time-consuming, error-prone and inconsistent. This is the place where automatic wire cutting and stripping machines come. These wire crimping and tinning machines are designed to cut, strip and prepare the wires quickly and accurately, making the wire processing very simple. With advanced technology, they can handle various wire types and sizes with minimal human intervention. For manufacturers and technicians, it is a game-changer.

Full Automatic Cutting and Stripping Machine (TA-DZX01)

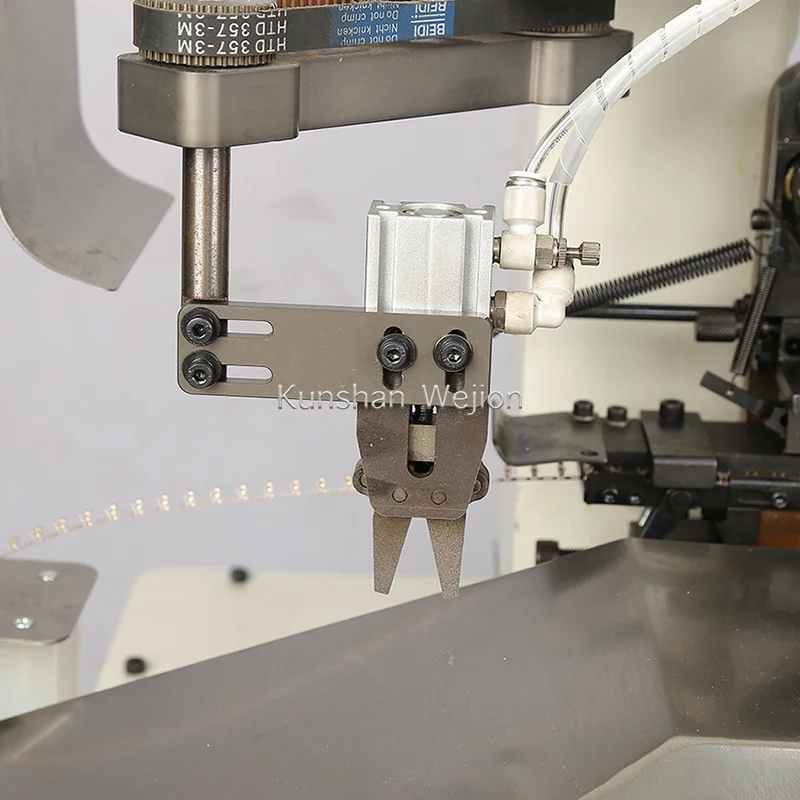

The TA-DZX01 full automatic wire cutting, stripping, and crimping tining machine is designed for sharp and accurate processing of 5 wires at once. This automatic cable processing machine integrates cutting, stripping, crimping and tinning, which is ideal for electrical and electronic applications.

Versatile Wire Processing

The TA-Dzx01 handles a wide range of wire types, including single wires and parallel wires, distribution in branches and various end treatments. Supporting wire gauge from AWG18 to 32#, it meets the needs of small to moderate electrical projects. Users can rely on its versatility for both simple and complex wire tasks.

Accurate cutting and flexible stripping

The automatic wire cutting and stripping machine cuts the wires between 10 mm and 600 mm with extraordinary accuracy, which keeps waste low and corresponds to quality. The stripping length ranges from 0 to 7 mm, adjustable to specific requirements. This accuracy ends with clean and reliable wire for strong electrical connections.

Powerful crimping and efficient tinning

With a crimping force of 2.0 tons, the TA-DZX01 secures the terminals for the wires, guaranteeing the terminal connection. Its tinning function prepares the wire end for stitches, improving conductivity and resistance to corrosion. This combination ensures that each processed wire is both mechanically and electrically sound.

High-Volume and User-Friendly Operation

TA-Dzx01 per hour saves 5,500 to 7,500 pieces, making it perfect for mass production. Despite its strong construction and advanced facilities, the machine is easy to operate. Its spontaneous interface allows operators to quickly learn and maintain stable workflows, saving time and effort.

Benefits of using our wire processing equipment

Using automatic wire cutting and stripping machines provides many advantages. They save time. A single machine can process hundreds of wires per hour, something that workers will take more time to do manually. Second, they improve accuracy. Manual cuttings can give birth to uneven or damaged wires, which can affect the quality of the final product. With these machines, every cut and bandage is accurate, ensuring uniformity in all wires.

Another benefit is security. Working with a knife or wire strippers can sometimes cause injuries. Automatic machines reduce the risk by safely handling the cutting and stripping process. They also reduce labour costs as an operator can manage multiple machines. For businesses, it translates to rapid production, better quality and low expenses.

These Industrial wire cutting equipment are highly adaptable. They can handle various wire gauges, lengths and insulation types. This versatility makes them ideal for small workshops and large factories.

Features of modern wire cutting and stripping machines

Automatic wire cutting and stripping machines are packed with features that make them efficient and easy to use.

An essential feature is programmable settings. The operator can set wire length, cutting speed, stripping length and more using a simple touchscreen interface. This allows quick changes between various wire types or projects.

High precision is another major feature. These machines use advanced sensors and cutting techniques to ensure clean cuts and correct stripping without damaging the wires. Many models also include automated error detection, which prevents the machine if a wire is wrongly or inappropriately aligned.

Versatility is a third feature. Multi-wire cutting and stripping machine can handle solid and trapped wires, single-core or multi-core cable and various insulation materials. Some machines may cut and strip several wires simultaneously, increasing productivity. Additionally, many machines have compact designs, making them easier to fit production lines without taking them too much space.

How Automatic Wire Cutting Machines Improve Efficiency

Efficiency is important in any manufacturing or assembly process. Automatic wire cutting and stripping machines improved efficiency by reducing manual labour and reducing mistakes. Since machines can cut and strip at high speed with constant accuracy, the time of production is significantly reduced.

High-speed wire processing machines also allow operators to focus on other functions. Instead of manually preparing each wire, workers can monitor multiple machines, ensuring that the production continues smoothly. In addition, automated machines reduce physical waste. Manual cutting often leads to errors, resulting in wasted wire. With accurate settings, the machine uses each wire efficiently.

Another efficiency gain comes from batch processing. Operators can program the machine to process hundreds of similar wires in a run. It is particularly useful for harness assembly, automotive wiring and electronics production.

Applications of Wire Cutting & Stripping Machine in Industry

In many industries, automatic wire cutting and stripping machines are widely used. In the motor vehicle field, these machines are required to make wiring harnesses, which add electrical components to vehicles. Accuracy and speed are important here, as small errors can also affect performance and safety.

In electronics, an electrical wire preparation machine helps prepare wires for circuit boards, equipment and other devices. They ensure the length of the wire and snatching ends, which are important for soldering and assembly. Telecom companies also use these machines to process cables for network installation.

Industrial equipment construction, renewable energy systems and aerospace areas also benefit from these machines. Anywhere the wires are required to be cut, snatched and prepared efficiently, automatic machines save time, reduce errors, and increase overall productivity.

Choosing the automatic wire cutting and stripping machine

Choosing the right machine depends on your specific requirements.

- Consider the types of wires you use. Solid wires, stranded wires, single-core, multi-core, and various insulation materials all require different machine capabilities. Make sure the machine you choose can handle your most common wire types.

- Think about volume and speed. If you process a high amount of daily wires, you need a sharp machine with batch processing capabilities. For small operations, a compact machine with easy programming ability can be more suitable.

- Another important factor is accuracy. Look for machines with an accurate sensor and advanced cutting technology. Reliable error and automated adjustment features will help maintain quality.

- Ease of use and maintenance are also necessary. Machines with intuitive interfaces, quick-change settings and accessible parts reduce downtime and make operations smooth.

Technology Uses for Our Stripping Machine Manufacturing

The technology behind the automatic wire cutting and stripping machine is impressive.

Advanced sensors detect wire conditions, thickness and insulation types. This ensures accurate cutting and stripping without damaging the wire. Some machines use Sarvo Motors for high-speed operation with excellent accuracy.

Programmable logic controllers (PLCs) and touchscreen machine makes it easier to set and replace parameters. Operators can save programs for various wire types, reduce the setup time for repeated tasks. High-quality blades and stripping tools are designed for durability and minimal wear, which ensures frequent performance on long production runs.

Wire end processing automation also allows for integration with other manufacturing systems. Machines can feed the wires directly into the harness assembly tools or packaging lines, making a spontaneous workflow. It reduces manual handling, increases productivity, and reduces the risk of errors.

Where to Buy Reliable Automatic Wire Cutting Machines?

If you are looking for trusted automatic wire cutting and stripping machines, Kunshan Weijiang Automation Equipment Co., Ltd is a reliable provider. They are experts in wire processing and harness assembly machines and solutions, offering high-quality devices that meet industry standards.

Their machines are designed for speed, accuracy and durability. Whether you need a compact machine for a small workshop or a high-capacity unit for large-scale production, a solution of Kunshan Weijiang. They also provide excellent customer support, help customers choose the right machine, install it and maintain it for long-term performance.

A reliable manufacturer ensures that your investment pays with consistent quality, low waste and better productivity. With the Kunshan automation company, you get the latest technology, versatile machines and expert guidance for all your wire processing requirements.