In today’s fast-growing industrial world, machines play a huge role in saving time and increasing quality. One such useful tool is the flat cable terminal crimping machine. This machine helps to connect wires and terminals strongly and reliably. A semi-automatic version combines modern technology with easy handling, making it a favourite option in many industries.

Semi-Automatic Flat Cable Terminal Crimping Machine (T-FW320)

The T-FW320 semi-automatic flat cable terminal crimping machine is a compact and efficient solution designed for electronics, automotive, and industrial applications. It handles wire harness separation and terminal crimping with speed and precision.

Comprehensive Terminal Crimping

This machine supports both single-hole crimping and multi-hole continuous crimping with quick adjustments. It works with different types of terminals, including cold-pressed copper and aluminium, as well as insulated terminals with plastic sheaths. By applying controlled pressure, the T-FW320 ensures a strong connection with low resistance, creating a safe and efficient conductive path.

Precision and Pressure Control

The T-FW320 delivers 2000KG crimping force, managed by a precision valve or servo motor. The pressure remains stable within a ±2% margin, meeting global standards such as UL and JIS. Its adjustable stroke design offers two options: 35mm for thin terminals and small-diameter cables, and 40mm for thicker or multi-core cables. This makes it compatible with wire gauges from AWG 28 to AWG 12.

Smart Automation Functions

The built-in micro-switch trigger system makes operation simple. After placing the cable and terminal, the operator only needs to press the foot pedal or button. The machine automatically performs the full crimping cycle in 3–5 seconds. It can also connect with testing equipment, allowing a seamless “crimping to detection” workflow.

Features and Advantages

With a modular design, quick-change crimping heads, and an adjustable wire fixture, setup is fast and flexible. The ergonomic height and protective LED-lit cover improve safety and comfort. Lightly durable, the T-FW320 reduces the cost compared to automatic machines, offering better stability than manual tools. This makes it an ideal option for laboratories, R&D centers and custom production lines.

Flat Cable Terminal Crimping Machines Working Principle

The function theory of a semi-automatic flat cable terminal crimping machine is still smart.

The operator keeps the flat cable stable in the stability of the machine. Then, the terminal is set in the correct position. With a leg pedal or a push of the start button, the machine uses pressure to press the terminal firmly on the cable.

The semi-automatic cable crimping equipment design means part of the process is done by the machine, while the operator controls the setup. This balance ensures accuracy by keeping the process flexible for various cable sizes and terminal types. The machine applies stable forces, which makes each cooperative consistent and reliable.

Unlike manual crimping, where strength and hand skills play a role, this machine guarantees uniform results. It also protects the cable from damage because the pressure is controlled and measured. This is why industries prefer semi-automatic crimping machines when they need both speed and accuracy.

Key Features and Technical Specifications

Modern semi-automatic flat cable terminal crimping machines come with many important characteristics. Most models are designed with a strong steel frame that ensures durability. They often include a digital control system that allows the operator to easily set pressure, speed and length of stroke.

Technical specifications may be different, but a normal machine can cover terminals within a certain size range, usually from small electronic connectors to large industrial equipment. The power source is often electric, and some models add pneumatic systems for additional strength. Many machines also include a safety cover that protects the user during the operation.

Another useful feature is the Quick Change tooling. This allows the operator to switch from one type of terminal to another in minutes. The wire harness terminal crimping machine also works quietly, which makes it suitable for factory floors. The combination of speed, safety and precision makes these machines an ideal fit for wire harness production lines.

Benefits of an automated wire and terminal crimping system

There are many benefits of using a semi-automatic flat cable terminal crimping machine.

- One of the biggest benefits is efficiency. The Industrial terminal crimping press saves time than manual methods and allows operators to process more cables over a shorter duration.

- Another benefit is accuracy. Each crimp is the same because the machine controls the force and movement. This means fewer mistakes and fewer rejected parts.

- Consistency in industries such as electronics and automotive is very important, where a small defect can also cause major problems.

- Flat ribbon cable crimping tool also improves security. Since the machine handles pressure, workers do not need to put heavy force on their hands. This reduces the risk of injury and fatigue.

- These machines are cheaper than automated people. They provide a balance of performance and cost, making them a smart investment for moderate and large businesses.

Applications in Cable and Wire Processing Industries

Semi-automatic flat cable terminal crimping machines are widely used in many industries. In the electronics industry, they are used to create reliable connections in devices such as computers, phones and home appliances.

In the automotive industry, they are required to produce wire harnesses that add electrical systems inside vehicles. From the car dashboard to the engine control, strong cable terminals are required everywhere.

The telecom industry also depends on these machines. Flat cables are often used in networking and communication devices, and ensure a safe link for crimping signal transfer.

Even in aerospace and medical fields, where quality standards are very high, precision flat cable connector crimping plays a role. These industries cannot risk bad connections, so they rely on machines that guarantee accuracy and reliability.

Technology is used to manufacture the Machine

Modern semi-automatic crimping machines are designed using high-quality materials.

The machine frame is usually made of hard steel to withstand heavy use. Criming dice is prepared from alloy steel or tungsten carbide, which ensures long life and wear resistance.

Technology also plays a big role. Many machines are equipped with a PLC (Programmable Logic Controller) system that allows easy control and monitoring. Anything also comes with touchscreen displays that clearly show settings and error messages.

The sensor is often included to detect the condition of the cable and confirm that the terminal is correctly crimped. This reduces errors and ensures that the process meets industry standards. The advanced lubrication system also helps in running the machine smoothly without continuous maintenance.

How to select the right flat cable crimping machine

Choosing the right semi-automatic flat cable terminal crimping machine depends on many factors.

- Think about the type and size of cables that you need to cover. Different machines support different ranges, so match the machine with their production requirements.

- Consider the amount of production. If you need only a few crimps per day, a basic machine will work. But if you run a busy factory, you will need a machine that can handle continuous operation without overheating.

- Check the tooling options. If you often switch between different terminal types, a machine with a quick-change is better. See also for safety facilities, such as protective cover and emergency stop buttons.

- Do not forget to evaluate the ease of use. A nice semi-automatic machine should also be simple to operate for new workers. After the sale, the availability of warranty and additional parts is also important.

Who Offers the Updated Crimping Machine at the Best Price?

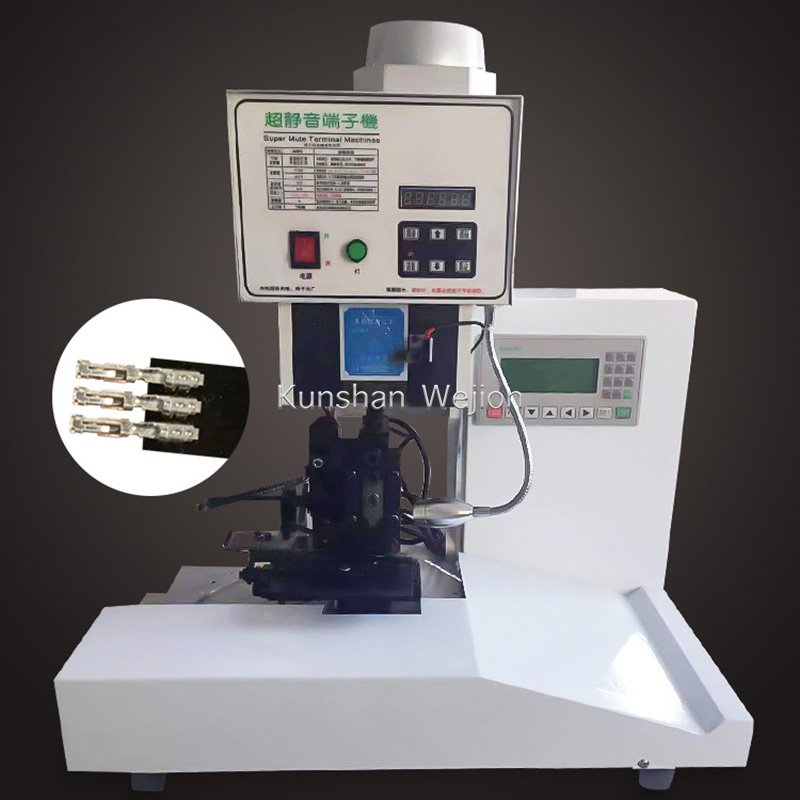

When it comes to purchasing the best semi-automatic flat cable terminal crimping machine, Kunshan Weijiang Automation Equipment Co., Ltd. is a reliable name. The company is well known for providing high-quality wire processing and solutions to harness assembly machines and competitive prices.

The Kunshan Weijiang focuses on innovation, durability and user-friendly designs. Their machines are designed to meet the demands of modern industries and are trusted by customers worldwide. With a wide product range, they provide electrical cable terminal crimping solutions for small, medium and large-scale businesses.

Another reason for choosing their excellent customer service. They provide professional assistance, training and maintenance to ensure smooth operation. For businesses looking to upgrade their production lines with reliable crimping machines, Kunshan Weijiang Automation Company is one of the best options.