In today’s workplaces, clean cuts are a must. They also need work that is both quick and steady. A six-wheel stripping machine has been made to meet both needs at the same time. It strips wire evenly and smoothly. It protects the metal core from the inside. It doesn’t need breaks and can keep going for hours. Workers don’t have to worry about getting tired hands. Managers can always look at consistent production. For teams that care about quality, this gadget will quickly become an essential part of their daily lives. Because of this, the factory floor can move more easily. As a result, shifts are more peaceful. It also makes people trust each wire that is finished.

Essential Thing for a Six-Wheel System

At the same time, a six-wheel stripping machine system grabs the wire from different sides. This hold is steady but not too tight. The force is evenly spread out along the wire. This balance is what makes the blade cut through the outer jacket. The copper or aluminum inside is still fine. The result looks neat and organized. It looks like there isn’t much difference between the strips.

Factories learn to trust the results when they do this over and over again. Several experts agree that this layout is essential for the best wire stripping machine for quick lines. It ends the doubt. Cuts that aren’t even are no longer possible. It is easy for both new and experienced workers to use.

Built for Stable and Clean Output

Stability is very important when making things on a large scale. The six-wheeled automatic wire stripping machine uses the same amount of force all the time. It doesn’t change based on mood or tiredness. This ongoing process reduces waste. The wires get less damaged. The budget is still easy to handle. Workers spend less time fixing mistakes. It’s easy to check for quality. Clean stripping also helps with the next steps, crimping and soldering. Customers are happy when the production area stays clean. This kind of device makes it easier to grow over time. It makes the daily work routine easier.

Where These Machines Are Used

You can see six-wheelers everywhere these days. They work well for both big and small businesses. Areas that are often used include:

- Industries that need a lot of cable assembly

- Companies that wire cars that put the safety of their customers first

- Control panel makers who need to start over

- Appliance makers use wires of different sizes

- Using special wires, new energy projects

These customers usually work with a company that sells six-wheel stripping machines that they can trust. The equipment and the help it gets over time are both important. Lines stay open because of great service.

Manual vs Automatic Stripping Machines

| Feature | Manual Wire Stripping Machine | Automatic Six-Wheel System |

| Speed | Slow and uneven | Very fast and steady |

| Skill need | High hand skill | Easy to learn |

| Consistency | Changes by user | Always stable |

| Fatigue | High for workers | Very low |

A manual wire stripping machine will work for smaller jobs or maintenance. It works well over short distances. But for big orders, automation is needed. Automatic systems save time. Also, working conditions are protected. Over time, they become more valuable.

Heavy Duty Work Without Damage

There are wires that are thick and strong. They have on strong coats. To do this, a strong wire stripping machine is made. The six-wheel grip holds the cable firmly. It won’t break or change it. The blade makes clean cuts through thick layers. This keeps the core from getting too many marks on it. You need to be very careful around power lines and safety wires. Damage may cause a failure to happen later. With the right tools, it’s easy to strip even the strongest wires. Engineers and customers can be sure of this.

CS-M300 Multi-Conductors Cable Stripping Machine

The CS-M300 cable stripping machine is made to work with complicated cables. This tool can strip the insulation off of several conductors at once. You can use different wire lengths in different configurations. Operators can easily change the parameters. It’s easy to understand and use the interface. The results are still neat and consistent. This will be helpful for factories that are always on the go.

Eventually, there will be some wire here and there. There will be longer ones on day two. A lot of people call it a smart stripping wire machine for mixed orders. It can be set up more quickly. It also keeps the quality high no matter what you’re doing.

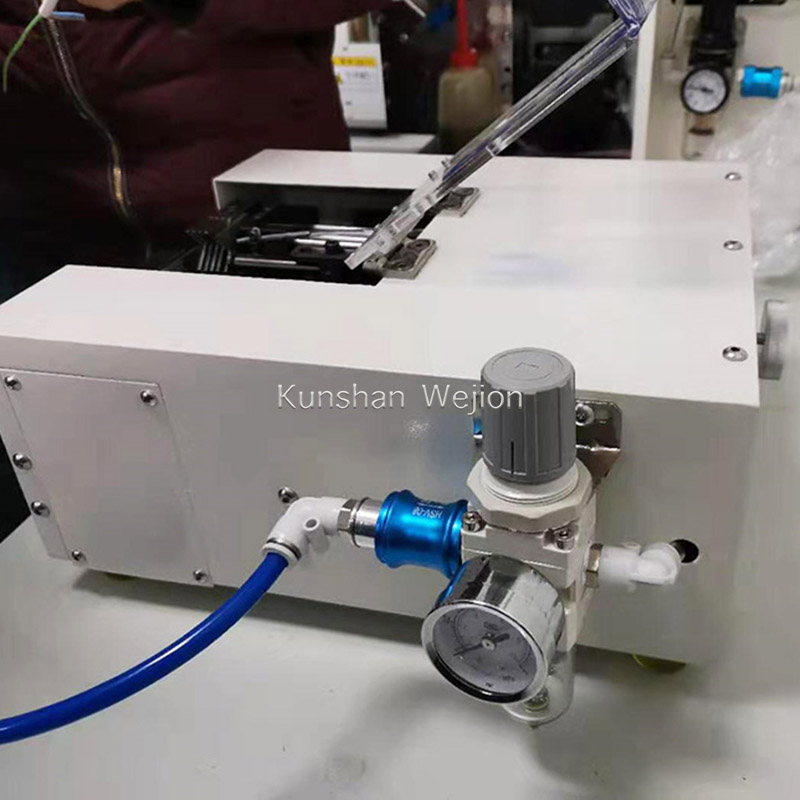

S-2015C Pneumatic Wire Stripping Machine

The S-2015C Pneumatic Wire Stripping Machine works by using air pressure. This gives you soft, mild power. Great for small, flexible multi-core wires. The stripping is done quickly and accurately. Thin cords won’t fray. It’s easy to take off coats. This model matches the lines when it comes to details. It goes well with an automated wire six-wheel stripping machine system. As a group, they get a lot done. Shops like how easy it is to use and how consistently it works.

S-2017C Universal Blades Wire Stripping Machine

The S-2017C’s Universal Blades Wire design includes a blade that can bend. You can use the same pair of blades on wires of different sizes. It’s easy and quick to change the blades. By doing this, we save time during shifts. It has a lot of uses in the wire processing industry. Both big factories and small businesses use it. Many people praise its performance and value for money. It stands out among the tools made by six-wheel stripping machine makers. It shows that you can get great results even with a simple design.

Safety and Operator Comfort

Worker safety is the most important thing today. Six-wheel setups let you use your hands-free. Guards keep fingers from getting hurt. Controls are set up so that they are easy to reach. Be quiet. Vibration causes less strain. This comfort is important for long periods of time. When workers are happy, they are more productive. They make fewer mistakes. This people-first approach to machine design creates a positive work environment. You get comfort and safety when you get high-quality.

Compact and Portable Options

Jobs can move to different places. For some jobs, you have to move around. Some specialized crafts use a portable laser stripping machine for wood from time to time. Small six-wheel tools are great for moving around when working with wire. People can go from one station to another. Great for small spaces. Being small doesn’t make you less powerful. These features make it easier to create flexible layouts. They are the best at being able to change with changing production needs.

Choosing the Right Machine Partner

Buying a machine is a long-term commitment. Look for a reliable company that makes stripping machines with six wheels. Check how fast they can help you. Please check to see if we can help with spare parts. Learning is also very important. A good friend can help you solve problems faster. They grow as your factory does. Strong help makes machines last longer. It protects your money from harm. Over time, consistent support builds trust.

Why Six-Wheel Machines are the Best

Six-wheel systems offer many clear benefits:

- Even pressure on all sides of the wire

- Clean and smooth cuts every time

- High working speed for big orders

- Less waste and fewer errors

- Easy training for new workers

These points explain why many call it the best wire stripping machine choice today. It fits modern needs well.

Reliable Provider for Six-Wheel Stripping Machine

Kunshan Weijiang Automation Equipment Co., Ltd. is known for stable and reliable wire processing tools. Their machines are used in many countries. They serve different industries. Their focus on quality and support stands out. Many factories rely on them for daily work. This trust comes from years of service. Their machines help lines run smoothly and safely.

Automation brings order to busy production lines. A six-wheel stripping machine system adds trust to every strip. Clean work builds strong products. A wise choice builds a strong business. Strip smarter. Work better.

FAQs

- What is a six-wheel stripping machine?

It is a machine that holds wire with six wheels. This gives a balanced grip and clean stripping.

- Is it better than manual tools?

Yes. It works faster. It gives more stable results than a manual wire stripping machine.

- Can it handle thick cables?

Yes. Many models act as a heavy duty wire stripping machine for strong cables.

- Who should buy one?

Factories, workshops, and cable makers with repetitive and large workloads.

- Where can I find a trusted supplier?

Well-known manufacturers, such as Kunshan Weijiang Automation Equipment Co., Ltd., are a good starting point.