Factories need speed and accuracy to stay ahead. Wires and cables are the lifelines of many industries, from cars to electronics. Cutting and crimping wires by hand takes time, and mistakes can happen. That is why more factories now use automatic wire cutting and crimping machines. These automatic wire processing machines make the work fast, smooth, and precise. They can handle thousands of wires in less time and with fewer errors.

Mechanism of Wire Cutting & Crimping Machine

An automatic wire cutting and crimping machine works like a smart assistant. It takes in raw wires, measures them, cuts them to the right size, and crimps the ends with perfect pressure.

The cable cutting and crimping equipment uses advanced sensors and software to make sure every wire looks the same.

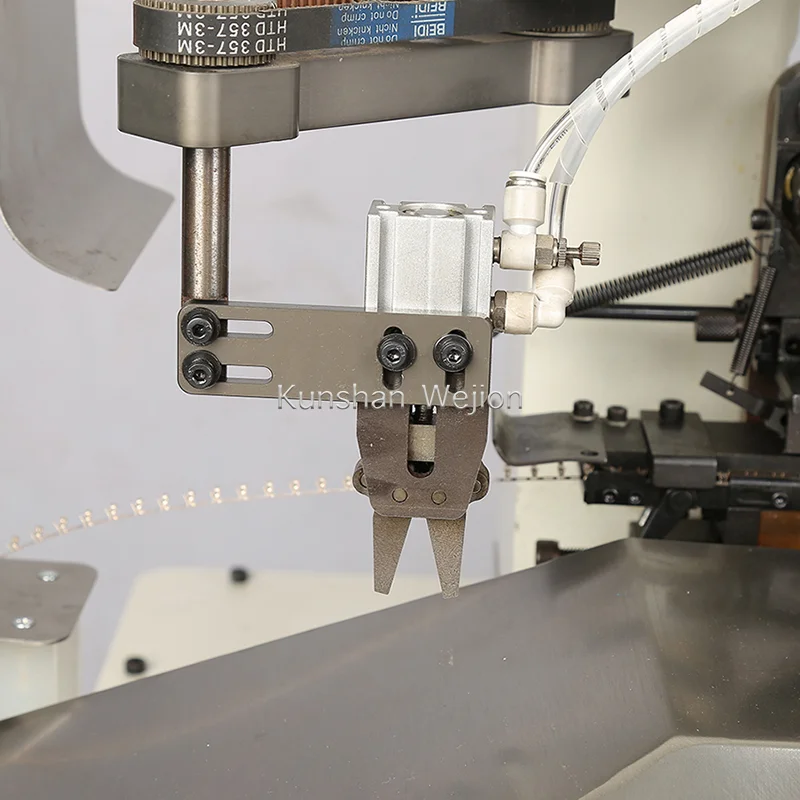

The cutting part uses sharp blades to slice wires quickly without damage. Then, the crimping part presses a metal terminal onto the wire. This creates a secure connection that is strong and reliable. The whole process happens in one smooth cycle, which saves both time and effort.

Unlike manual work, the machine does not get tired. It can repeat the same task for hours with the same level of quality. This is why industries that need high volumes of wiring trust this technology.

Full Automatic Wire Cutting and Crimping Machine-TA-D01

The TA-D01 full-automatic wire cut strip and single-end crimming machine is designed for sharp and accurate wire processing. It combines wire cutting, stripping and crimping to a smart system, making it an ideal option for industries such as electronics, automotive and telecommunications.

Full-process wire handling

This electrical terminal crimping machine provides complete wire processing in a cycle. It can cut the wires, strip an end, bend, and cover the terminals with accuracy if necessary. Two versions are available: with a conversion for a particular job and without one, which is more cost-effective.

High speed and precise production

The TA-D01 is designed for mass production. It can process 4,000 wires per hour, ensure high production without losing accuracy. The length of the wire can range from 45 mm to 9,999 mm, while the stripping length is accurate within a very short error margin.

Strong crimping and reliable performance

With 2.0 tonnes of crimping force, the machine makes strong and safe connections. Built-in wire detections and strats ensure smooth operation, while intelligent parameter storage makes it easy to switch between different wire types.

Benefits of using a wire stripping and crimping system

The biggest advantage of this high-speed wire harness machine is speed. A task that takes hours by hand can be done in minutes with the machine. It improves production rates and helps factories to complete the time limit easily.

Another profit is accuracy. Human hands can slip, but a machine is always cut with the same accuracy and crimps. It ensures frequent product quality, which is very important in industries such as motor vehicles and electronics.

Cost savings also play a big role. By reducing errors, waste and manual labour, factories save money in the long run. Security is another advantage. Since the machine handles sharp equipment and strong pressure, workers face low risks.

Technology improves reliability. Wires with correct crimps are less likely to fail in use. This makes the final product strong and more reliable for customers.

Application in modern wire and cable production

In many industries, automatic wire cutting and crimping machines are used. In the motor vehicle industry, they are important in making wiring harnesses for cars, trucks and buses. Each vehicle has hundreds of wires, and these machines ensure that every time it is ready.

In electronics, they are used for gadgets, equipment and computers. The wires inside these products should be small, clean and safe. A machine ensures that they meet high standards.

In telecommunications, wires and cables should handle high data speeds. Accurate cuttings and crimping ensure that the connections are reliable. These machines are also used in aerospace and medical devices, where safety and precision are non-negotiable.

Even in domestic products, such as washing machines and refrigerators, these machines play a role in wiring. This shows how broad applications are in today’s world.

Choosing the automatic wire cutting and crimping machine

It is very important to choose the right precision wire cutting tools for any factory.

The first thing to investigate is the wire range. Ensure that the machine can handle the thickness and type you use.

Look at the speed of production. If you need thousands of wires per day, choose a high-speed model. The accuracy is another important point. Always select a machine with an advanced sensor and error-locomotive system.

Ease of use is also in cases. A machine with a user-friendly screen and quick setup will save time for operators. Stability should not be ignored. A strong construction ensures that the machine lasts for years with minimal repair.

Consider the post-sales support. A reliable supplier provides training, spare parts and service when needed. This brings a big change in running your production line smoothly.

Get a full automatic wire cutting and crimping machine

If you are looking for a reliable industrial wire crimping solution, Kunshan Weijiang Automation Equipment Co., Ltd. is a great option. The company specialises in wire processing and harness assembly machines. They offer smart, durable and efficient tools designed for modern industries.

They focus on both quality and customer service. Their machines are designed to handle high-volume functions without losing accuracy. They also provide complete solutions for various industries, including motor vehicles, electronics and more.

By selecting the Kushan Weijiang Company, you are not just buying a machine. You are getting a partner who understands your production needs. With their strong reputation and wide range of products, you can rely on their wire processing and improvement of harness assembly functions.