In today’s fast-moving world, machines help us work faster and better. One such tool is the automatic wire cutting and stripping machine. This machine is used to cut wires to the right length and remove their outer cover without damaging the inner part. It’s very helpful in making electric products and wiring systems.

With such a lot of wires used in vehicles, homes, gadgets, and huge machines, it’s critical to have the proper gear. Manual reducing and stripping takes quite a few efforts and time. But wire processing equipment does it fast, cleanly, and with the identical result each time. That’s why many factories and companies use those machines every day.

How does an automatic wire cutting and stripping machine work?

This Wire Cutting and Stripping Machine works in a simple way. The wire is fed into the device. A motor pulls the wire to a set duration. Once the wire reaches that length, sharp blades are available to reduce it. Then, the subsequent part of the machine moves in to strip the wire. Stripping manner, it removes the plastic cowl from the ends, displaying the metal inside.

This procedure takes the most effective seconds and may appear time and again without fail. The system uses sensors and software to make sure every wire is reduced and stripped precisely to the same length. Some machines may even work on many wires straight away.

Full-automatic wire cutting and stripping machine is available online

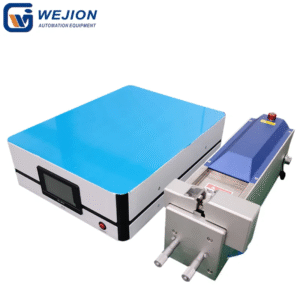

The CS-8030H is a smart and full-automatic wire cutting and stripping machine. It can handle cable wires from 0.5 to 30mm² and process up to 8 wires at once. Unlike old machines, it uses belt feeding instead of wheels. This makes wire feeding smoother and leaves no marks on the wire skin. You can also add a take-up device for long wires and a code printer to mark wires with codes. The take-up keeps wires neat, and the printer lets you choose where and how the code looks. The CS-8030H is fast, clean, and easy to use.

Features of a Wire Cutting and Stripping Machine

The automatic Wire Cutting and Stripping Machine has many remarkable capabilities.

- It ought to be rapid. Speed topics, in particular in massive factories in which lots of wires are needed every day. These machines can method hundreds of wires in only a few minutes.

- The machine must be accurate. Every wire must be cut to the same size. The strip length must also be exact. Even a small mistake can cause big problems in electrical work.

- A good machine must handle different wire sizes. Some wires are thin and soft. Others are thick and tough. The machine should adjust easily for all kinds of wires.

- It should have a user-friendly screen or control panel. This makes it easy to set the wire length, strip size, and other settings.

- It should be made of strong and lasting parts. The blades must stay sharp. The motors must work smoothly. If the machine breaks often, it will stop your work.

Benefits of Using an Electric Wire Cutting and Stripping Machine

Using automatic wire processing equipment comes with many benefits. The biggest one is saving time. These machines are super fast. What would take a person one hour, the machine can do in just a few minutes.

Another great benefit is saving money. With faster work and less waste, businesses spend less on materials and labor. Over time, the machine pays for itself.

It also improves work quality. Every wire comes out perfect—same length, same strip—every time. There’s no guessing or checking needed.

These machines also make work simpler for people. Instead of spending all day slicing and stripping with the aid of a hand, employees can run the machine and do other responsibilities at the same time.

Automatic machines lessen wire damage. When stripping wires by way of hand, it’s cleaner to strip into the metallic inner. But these machines are very precise, so the wire remains sturdy.

Using such machines manner higher protection. Sharp tools are dealt with by using the system, not with the aid of people. This lowers the chance of cuts or accidents within the place of business.

Applications of a Programmable Wire Stripping Machine

Wire cutting and stripping machines are used in many fields. In the auto enterprise, these machines assist in making the wire harnesses that join a vehicle’s lights, engine, and more. Every vehicle has many wires, and these machines help cause them to speed and as they should.

In the electronics enterprise, these machines assist construct wires for gadgets, telephones, TVs, and computer systems. These gadgets need small and neat wires, and the machines are best for the process.

In home appliances, like washing machines and fridges, wires join parts. These machines assist in cutting and stripping the wires needed for safe use.

They are also used within the aerospace and protection fields. Here, wires ought to be perfect because even small mistakes can be dangerous. The machines help ensure every wire is simply right.

Even in creation and energy systems, these machines are useful. They prepare wires for homes, homes, and machines that want clean and strong wiring.

Choosing Best Automatic Wire Cutting & Stripping Machine

When choosing a wire harness processing machine, there are a few things to reflect onconsideration on.

- Take a look at the types and sizes of wires you want to paintings with. Make certain the device can cope with the one wire.

- Think about how fast you need it to be. If you have to make many wires every day, pick a high-speed machine.

- Check the accuracy. A good machine will cut and strip the wire the same way every time. Look at reviews or test the machine to be sure it works well.

- Check if the machine is easy to use. A simple screen, buttons, or settings will help workers do their job better and faster.

- Think about safety too. Choose a machine that shuts off if something goes wrong. This helps keep workers safe and protects your investment.

- You should also look at the build quality. Strong metal parts, sharp blades, and good motors make the machine last longer.

Get a better quality and high-speed wire cutting machine

If you are looking for a high-quality and trusted brand, Kunshan Weijiang Automation Equipment Co. is a great choice. This company is known for making smart and strong automatic wire cutting and stripping machines for wire processing and harness assembly.

Kunshan Weijiang offers many types of machines that are fast, easy to use, and long-lasting. Their machines are built to help save time, reduce waste, and improve work quality. They offer helpful support and custom solutions for all kinds of wirework.

Whether you work in car manufacturing, electronics, or building systems, Kunshan Weijiang has the right tools for you. Their machines are made with care and tested for top performance. They focus on making machines that help your team work better and faster.

Choosing Kunshan Weijiang means you’re getting an Industrial wire cutting solution that’s made for real work—strong, smart, and ready to go. Their goal is to give customers the best experience with machines that last long and work well every day.