In today’s fast-moving industries, wire winding machines are very important. These machines help in winding wires neatly and safely, making work faster and more organized. Whether it is for electric motors, transformers, or cables, a good machine can make a big difference. But here’s the thing—not all machines are the same. Picking the right wire winding machine is important, but choosing the right manufacturer is even more important. The right automatic wire winding equipment suppliers ensure quality, performance, and support. So, why does choosing the best wire winding machine manufacturer matter and what to look for when making this big decision?

Understand Your Business Needs and Wire Specifications

Before you pick a wire Winding Machine Manufacturer, you want to recognise your business needs. Not all groups work the same. Some might also want to wind thick copper wires, while others work with skinny, delicate wires. If you pick out the wrong system, it may not work well. That’s why you have to first reflect on the type of cord you operate, how rapidly you want to supply it, and how long the machine must ultimately run.

A reliable electrical winding machine manufacturer will recognise this. They will ask you questions to analyse more approximately your workings. They will no longer simply sell a device—they will offer a solution that suits your needs. This is why the first step is understanding your twine length, substances, and the amount you want to provide every day. Only then can you pick the right partner.

Check the Manufacturer’s Industry Experience and Reputation

Experience matters a lot. A wire harness winding machine provider who has been in the industry for many years knows how to make machines that work better and last longer. They have seen what works and what doesn’t. This means their machines are more likely to give you fewer problems.

Also, a company with a good name in the market usually means people trust it. You can check reviews online or ask other businesses about their experience. A good manufacturer will always try to keep their customers happy. They will offer help even after the machine is sold.

If the company has worked with other big companies, that’s a good sign too. It shows that they can meet high standards. So, when choosing a wire winding machine manufacturer, make sure they have been in the business for a long time and have a good name.

Evaluate Product Quality and Machine Features

Quality is one of the most important things. Cheap and high-speed wire winding systems might save you money now, but they may break down often. That will cost you more in the long run. Good machines are made from strong materials. They can run for hours without any problems.

Also, think about the features the machine offers. Does it have automatic wire cutting? Can it count how many turns it makes? Is it easy to use? All these features can save time and make your work easier.

A good manufacturer will focus on quality and performance. Their Industrial wire winding solutions will be tested before shipping. They will come with manuals, training, and safety features. So, always check what the machine can do and what it is made of before buying.

Review Customization Options and Technological Capabilities

Every business is different. Some may need faster machines. Others may need special shapes or sizes. That’s why it’s helpful if the manufacturer offers customization. A good company will listen to your needs and adjust the machine design to match.

Today’s machines are smarter than before. Some machines can be controlled by a computer. Others can save data and show reports. These smart features help you keep track of your work. They also help in finding problems quickly.

The cable winding machine production company will keep up with the new generation. They will provide machines that make your activity less difficult, quicker, and more secure. If you want to grow your business, those present capabilities can assist a lot.

Compare Pricing, Warranty, and After-Sales Support

Money is usually a topic. But going for the most inexpensive option isn’t always the best. It’s better to consider the cost. What do you get for the charge you pay? A device may cost extra, but if it lasts longer and works better, it saves you money later.

A suitable wire Winding Machine Manufacturer will provide truthful fees and clean phrases. They may also offer an assurance. This warranty offers you peace of mind. If something is going wrong, you know you’re blanketed.

But what happens after the sale? A strong after-income team could be very important. You may need schooling, spare parts, or help fixing the machine. A trusted producer will continually be there whilst you want them.

Assess Delivery Timelines and Global Supply Reach

Time is money. If your device takes too long to reach, your work may be prevented. That’s why it’s vital to select a producer who supplies on time. Ask them how long it takes to construct, test, and deliver the machine.

Also, can they ship worldwide? A wire Winding Machine Manufacturer with a global supply reach is helpful if you are in another country. They will know how to ship safely and quickly. Some companies even have offices in different countries. This makes getting help even easier.

So, always ask how long the delivery takes and if they have worked with clients in your area before. This helps avoid delays and problems.

Different Types of Wire Winding Machine

There are many types of wire winding machines, and each has its own job.

- The first type is the coil winding machine. It is used for winding wires into coils. These are often found in transformers or motors.

- Next is the bobbin winding machine. This machine winds wires around a bobbin, which is used in many electrical tools. It is good for thin wires and fine work.

- The toroidal winding machine is another type. This one is used to make ring-shaped coils. These coils are used in high-frequency electronics.

- There’s the armature winding machine. It is used to wind wires on motor parts. These machines must be very accurate.

- We have automatic winding machines. These machines can work without a person watching all the time. They are great for big factories that need to make many products every day.

Contact a Good Quality Wire Winding Machine Manufacturer

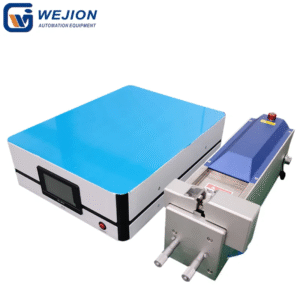

If you’re looking for a trusted name, one great choice is Kunshan Weijiang Automation Equipment Co. This custom wire winding machine manufacturer is known for making strong and smart wire winding machines. They offer full solutions for wire processing and harness assembly.

Kunshan Weijiang has years of experience. Their machines are used in many countries. They focus on quality, safety, and new technology. Whether you need coil winding, bobbin winding, or cable assembly, they can help.

They also offer great support. If something goes wrong, their team is ready to help. They understand that your time is valuable. That’s why they work hard to deliver machines that are ready to go and easy to use.

With Kunshan Weijiang, you get more than just a machine. You get a partner who wants your business to grow. They listen, customize, and always look for ways to make things better for you.