In today’s fast-moving world of factories and machines, speed and accuracy are very important. Businesses want tools that can do the job fast, clean, and without mistakes. One such smart tool is the ultrasonic cutting technology. This machine is not just fast—it is also very sharp, clean, and quiet. It helps many industries cut materials in the best way possible.

We’ll explain what ultrasonic high-speed cutting machines are. It will cover how they work, their best features, and where they are used.

What Is an Ultrasonic High Speed Cutting Machine?

An ultrasonic high-speed cutting device is a special type of cutter. It uses ultrasonic waves—which are sound waves we can not hear, to cut through materials. These waves vibrate very rapidly, more than 20,000 instances in keeping with 2nd. When these vibrations reach a blade, the blade moves fantastically quickly. This speedy motion allows the blade to slice through special materials with tremendous ease.

Unlike ordinary cutters, ultrasonic cutting doesn’t require lots of pressure. The blade glides through the cloth smoothly. There is also less heat and much less friction. In this manner, tender, sensitive, or sticky materials don’t get broken at the same time as slicing. The result? Clean, smooth cuts that look perfect whenever.

Key Features of Precision Ultrasonic Cutter

Ultrasonic high-speed reducing machines come with many useful features.

One of the satisfactory capabilities is remarkably high precision. These machines can cut very small or skinny parts precisely the way you want. This allows less waste and saves substances.

Another exceptional function is fast slicing speed. Because the blade moves fast, you may do more work in much less time. This is good for factories that want to make many components each day.

The machines also live cool and clean environment. Since there’s much less warmth, you gained’t see melted or burnt edges. That method makes the final product appear neat. There is likewise little or no dirt or mess, so your workspace remains easy too.

Most ultrasonic cutting machines are easy to use. Many include touch displays or simple buttons to set the speed and strength. Some even keep in mind your settings, which saves time for the duration of repeat work. Safety is another plus. These machines have smart sensors and shut-off systems to defend people during use.

Common Industrial Applications Across Various Sectors

Industrial ultrasonic cutting systems are used in lots of industries these days.

In the automobile industry, they cut foam, rubber, and material utilized in automobile seats, doors, and dashboards. These substances are soft, and ordinary blades can also damage them. But ultrasonic cutters manage them easily and neatly.

In the textile industry, these machines reduce synthetic fabrics like nylon or polyester. Regular slicing gear could make material edges fray or burn. Ultrasonic cutters remedy this with the aid of sealing the rims while slicing. This maintains the fabric strong and easy.

The electronics industry makes use of ultrasonic cutting machines to cut metals, wires, and smooth plastics. These components are small and need high precision. Ultrasonic machines are best due to the fact they cut easily without negative different elements.

In the packaging and meals industry, ultrasonic cutters are used to reduce sealed wrappers and packaging materials. They can even cut food gadgets without sticking. This helps make secure and smooth meal products.

Even the clinical industry uses this non-contact ultrasonic cutting process to reduce surgical masks, gowns, and other hygiene products. Since the cuts are easy and the method is safe, ultrasonic machines are best for medical use.

Comparing Ultrasonic Cutting to Traditional Cutting Methods

Traditional reducing equipment, like saws or knives, uses stress to cut. This stress causes warmth and friction. As a result, tender materials may also get burnt or torn. Also, the edges are frequently difficult and messy.

Laser slicing is another method utilized by some industries. While lasers are speedy, in addition they also produce high heat. This can warp or burn substances like plastic or foam. Lasers also want more power and are usually costly to maintain.

Ultrasonic cutters are higher because they require little force. The blade does not press hard against the material. It simply vibrates and slices cleanly. There is almost no heat, so delicate gadgets live safely. Plus, there may be no need to sharpen blades frequently because ultrasonic vibrations do maximum of the work.

Ultrasonic cutting also makes less noise and creates less dust. This makes the workspace cleaner and more comfortable. So, while in comparison to conventional reducing, ultrasonic cutting is more secure, faster, and cleaner.

Calculating the ROI: Is It Worth the Investment?

Buying an ultrasonic high-speed slicing gadget may also seem highly-priced at everything. But when you observe the whole photo, it could be a totally clever investment. Let’s see how.

- A less material waste manner extra savings. Since the cuts are very accurate, you won’t waste luxurious materials.

- These machines cut quicker, so that you can finish more work in less time. In that manner, you can take on more orders and develop your business.

- You save money on hard work and blade replacements. One device can do the task of many workers with the use of hand gear. And because the blade doesn’t wear out speedily, you gained’t want to update components frequently.

- The best of your product will improve. Smooth, easy cuts imply fewer problems in the long run. Happy customers are much more likely to go back and order extra.

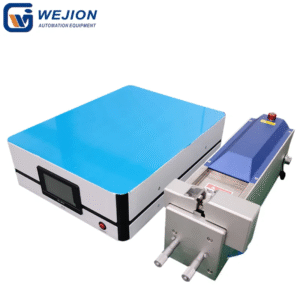

Good example for high-speed cutting machines

The CW-BU120 ultrasonic tape and label cutting machine uses advanced ultrasonic technology for fast and precise cutting. Its high-frequency vibrations deliver smooth, clean edges without burrs on many types of tapes. Designed to be compact and easy to use, this machine provides reliable performance and high efficiency, making it a smart choice for all your tape and label cutting needs.

Choosing the Best Automated Ultrasonic Cutting Machine

When selecting an Ultrasonic high speed cutting machine, consider your wishes.

- Start with the sort of fabric you’ll be cutting. Some machines are higher for tender substances like fabric, while others can reduce rubber or thin metal sheets.

- Reflect on how much cutting you may do. If your business needs to reduce large amounts quickly, select a gadget that is high-speed and heavy-duty. Make sure the device is the proper size in your workspace.

- Check the device’s manipulation system. It has to be smooth to recognize and use. Some machines have clever touch screens that store your settings. This makes painting quicker and easier in your group.

- Ensure the device has protection features like vehicle close-off or emergency buttons. This will assist in defending employees and reducing accidents.

- Pick out a reliable provider. Buying from an amazing organisation manner you get an extremely good machine and top-quality assistance.

Get an advanced ultrasonic cutting solution

If your industry works with wires or harnesses, you need machines that reduce and collect wires smartly. One properly company that offers those machines is Kunshan Weijiang Automation Equipment Co. They are recognized for making strong, clean-to-use machines for wire processing and harness assembly.

Kunshan Weijiang offers ultrasonic fabric cutting equipment that can strip, reduce, twist, and crimp wires. Their tools are fast and very correct. This helps companies make clean, dependable wiring for automobiles, machines, and electronics.

Their machines also include smart features and sturdy support. If you need assistance or upkeep, their team is prepared to help. This makes them a top desire for companies searching for wire processing solutions.

If you’re looking for gear that keeps time, reduces wires with precision, and helps build the best harnesses, Kunshan Weijiang is a name you can trust.