In today’s fast-moving industrial world, cutting belts the right way matters a lot. Many businesses rely on strong belts for machines, packaging, or transport. To get clean cuts every time, industries use special tools like cold knife belts cutting machines. These Industrial belt cutting equipment are known for their speed, safety, and accuracy. They help businesses save time, reduce waste, and improve work quality. If your business deals with belt materials, it’s time to learn why cold knife cutting machines are the best fit for your needs.

Understanding of Cold Knife Belts Cutting Machine

A cold knife belt cutting device is a tool that cuts various kinds of belts the usage of a sharp blade at room temperature. Unlike warm knife machines that use heat to soften and seal edges, a cold knife gadget slices the material cleanly without burning or melting it. This makes it best for cutting rubber belts, nylon tapes, or fabric belts used in lots of industries.

These machines are open automatically and can be programmed to cut belts to a set length. They are broadly used in cable assembly, automotive, packaging, and textile industries. The bloodless slicing technique gives a clean, direct side and prevents harm to sensitive substances.

Top-Rated Cold Knife Belts Cutting Machines on the Market

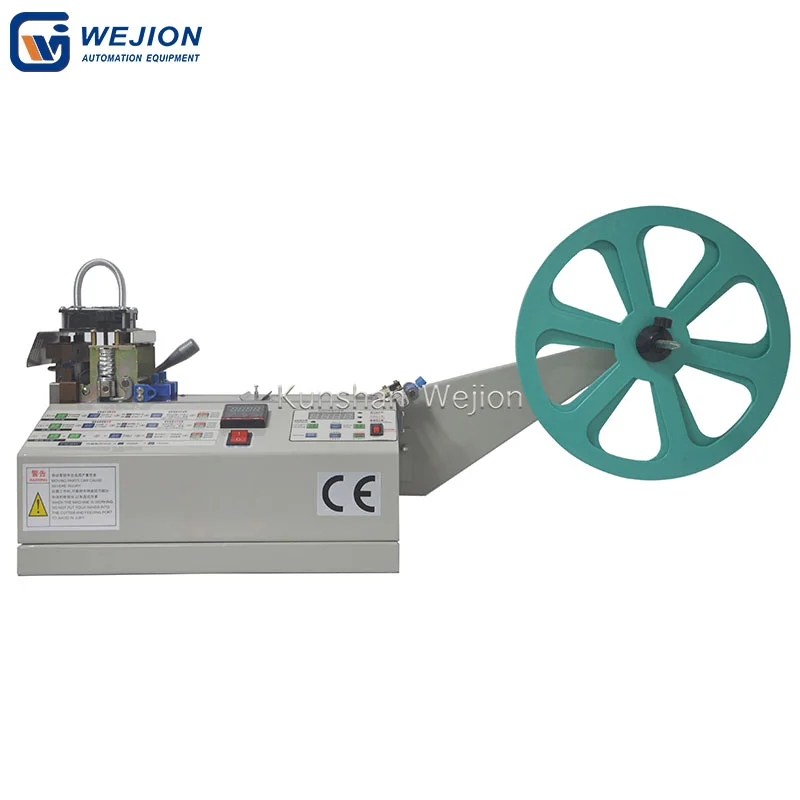

There are many great cold knife belt cutters out there, but one machine that stands out is the CW – B102. This model is not just a cold knife cutter—it also supports hot knife cutting. It’s a smart choice for businesses that need both cutting methods.

The CW – B102 is a cold blade cutting system. It’s built for speed and accuracy. It cuts tape, belts, or trims into exact lengths with little error. Thanks to its cold and hot knife features, it works well with garment trims, packaging tapes, and many belt types.

This non-thermal belt cutter is compact and easy to fit on a table. It has a digital control system that lets you set the length, speed, and cutting mode. The CW – B102 is known for being cost-effective while offering high performance. That makes it a favourite in factories and workshops.

Key Features to Look for in a Cold Knife Cutting Machine

When choosing a cold Knife Belts Cutting Machine, it’s critical to understand what functions count.

Look for a system with high cutting accuracy. The better the precision, the fewer errors you get in your cuts. Next, make sure the system has robust blades that last over the years. Durable blades imply much less renovation and decrease prices.

Another helpful feature is an automated feeding machine. This lets the machine pull and cut the cloth on its own, saving hard work and boosting speed. Also, check for user-friendly controls. A simple touchscreen or button panel facilitates employees’ research and use the system quickly.

Think about safety. Machines with guards, sensors, and emergency stop buttons help protect the operators. A good cold knife cutting machine should work fast, stay safe, and give clean, perfect cuts.

Why Precision Tape Cutting Machine Is Ideal for Industrial Belt Processing

Computerized cutting machine for belts is the top choice for many industries.

- One reason is that it does not use heat. That means it won’t burn or melt the belt’s edge. This is very important for belts made of rubber, PVC, fabric, or coated materials. The cut stays clean, and the belt’s shape doesn’t change.

- Cold knives work well on different materials. Whether the belt is thick or thin, wide or narrow, a cold knife can handle it. It gives the same neat cut again and again. This helps businesses keep product quality high.

- Another benefit is that cold knife machines reduce fire risk. Since they do not use heat, they are safer in workplaces with flammable materials. Plus, they use less power than hot knife machines, making them energy-efficient and cost-effective.

Choose the Heavy-duty strap cutting machine

Not all belts are the same. Some are gentle and stretchy, whilst others are stiff and difficult.

- To pick the right bloodless knife cutting system, first check the kind of belt you operate. If it’s thick or has many layers, you want a machine with a sturdy motor and a pointed blade.

- Think about what number of belts you need to reduce each day. For low-volume jobs, a basic desktop cutter might be enough. But if you’re cutting hundreds or thousands of pieces daily, go for a high-speed machine with automatic feeding and stacking.

- The width of your belt also matters. Some machines only cut narrow belts, while others can handle wide ones. Always match the machine size to your material.

- Don’t forget to look at ease of use. Your workers should be able to set up and run the machine without needing special training. Simple controls and easy blade changes save time and reduce mistakes.

- Consider your workspace. A compact, desktop model is great for small factories. Bigger machines need more space and power, but are better for high-volume cutting.

Trusted Manufacturers for Cold Knife Belts Cutting Solutions

When buying a system for your business, the emblem subject. One company known for quality is Kunshan Weijiang Automation Equipment Co. They make Precision Engineered Solutions for Wire Harness Processing, and their machines are trusted by many industries.

Kunshan Weijiang builds cold knife cutters that are strong, fast, and reliable. Their machines come with smart features like digital settings, automatic feeding, and safety systems. They are made to last and are easy to keep in good shape.

This company also offers great support and training. If your team needs help using the machine, their experts can guide you. Many businesses choose Kunshan Weijiang because they want quality machines that work well and last long.

Besides cold knife cutting machines, they also make wire stripping, reducing, and cutting machines. If your factory works with cables, tapes, or belts, this brand has everything you need.