Advanced Automatic Tape Wrapping Machine for Cable Processing

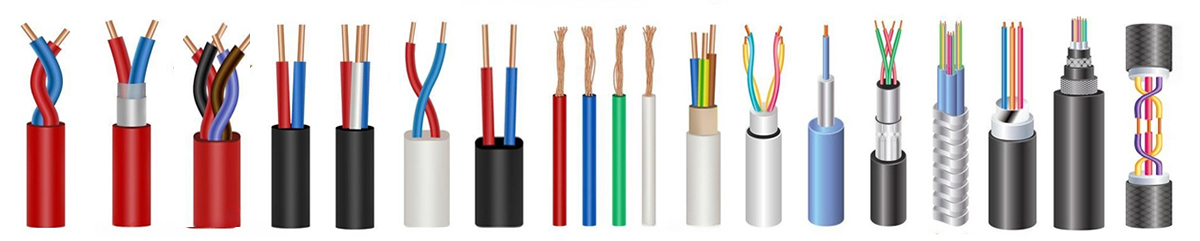

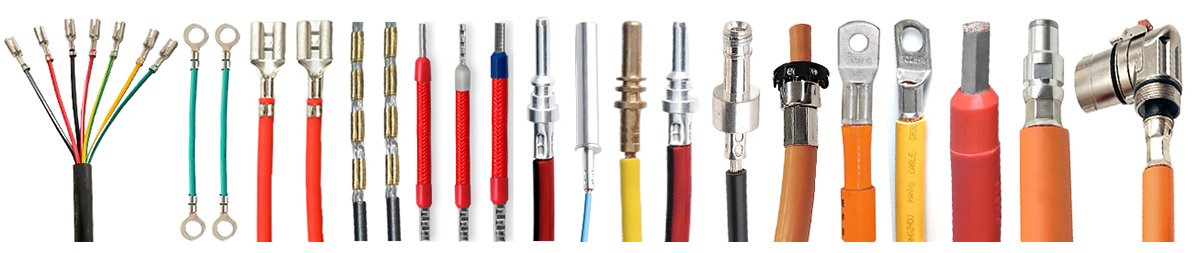

Cables are used in everything around us—from home electronics to large machines. But before cables can be used, they must be safe, neat, and strong.

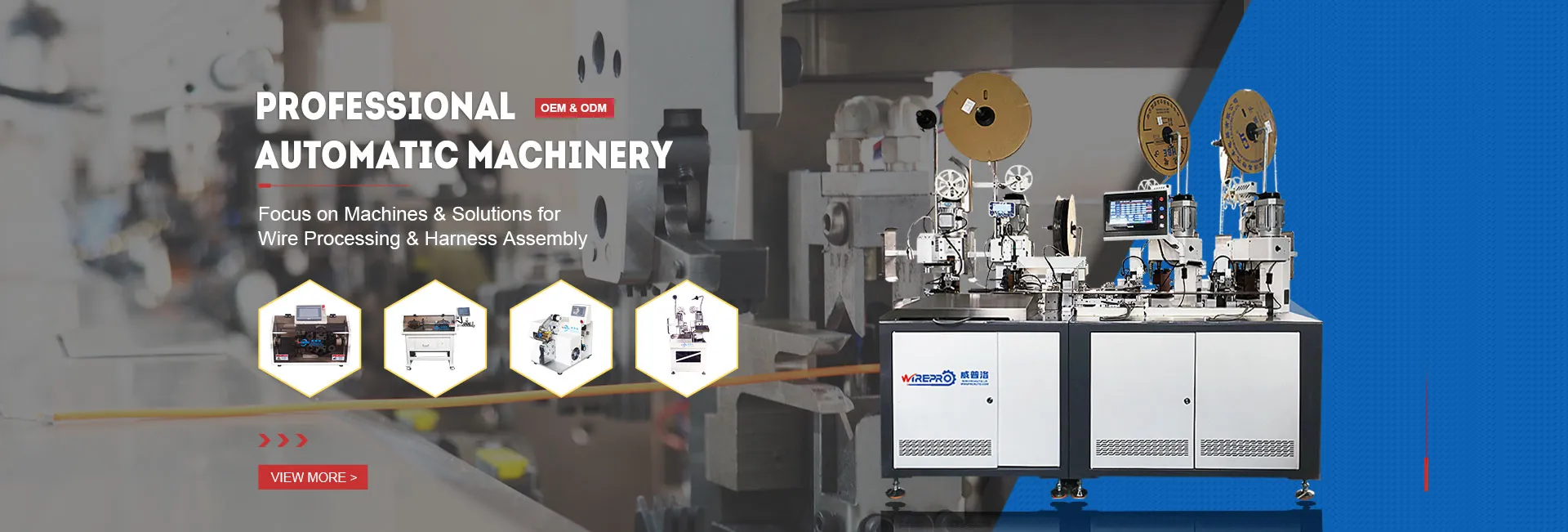

One-Stop Solutions for Wire Stripping, Crimping, Coiling, and Tube Cutting

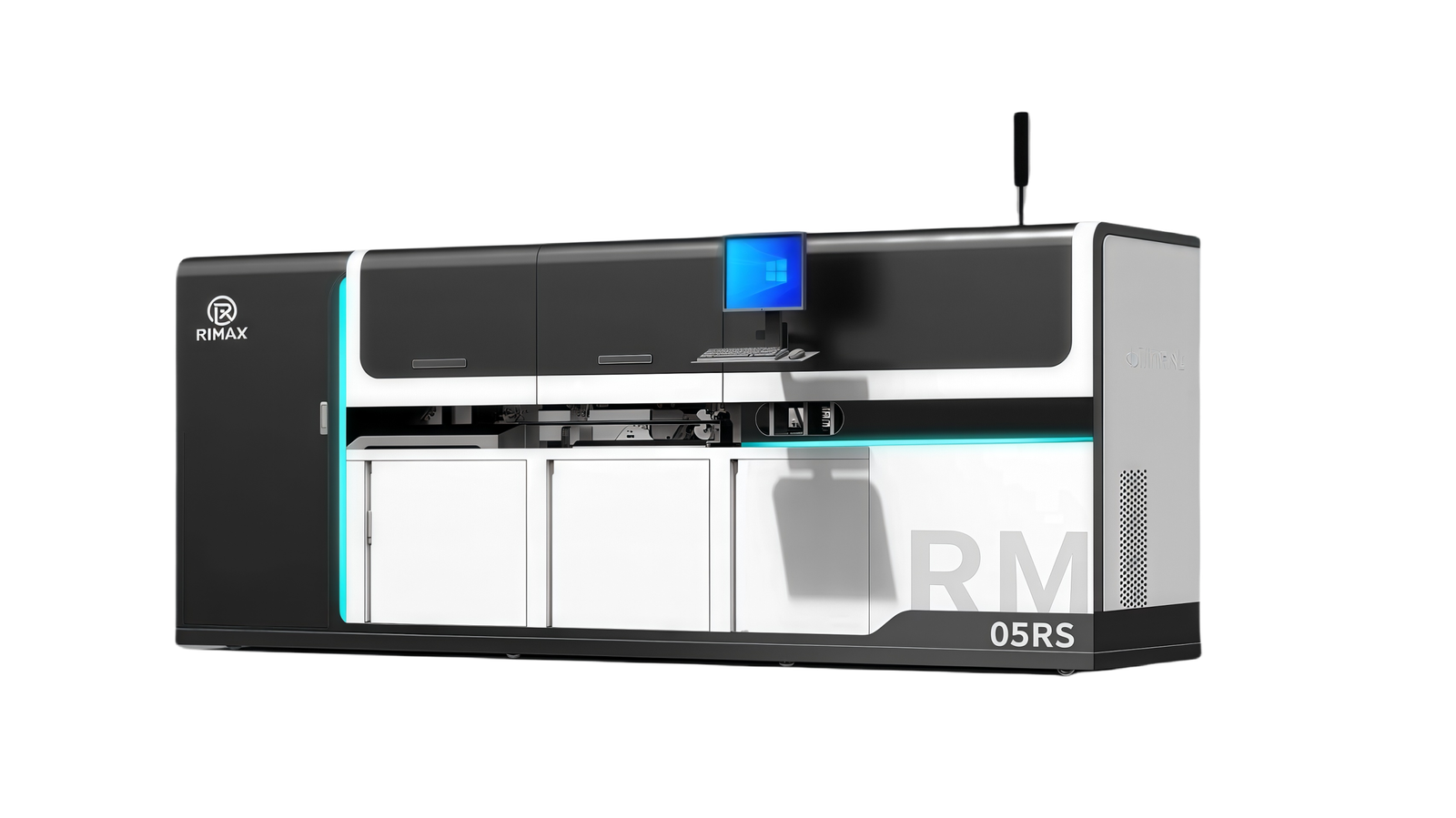

Exceptional Value Proposition with Highly Competitive Pricing: Optimize Cost-Efficiency in Harness Processing Equipment Procurement

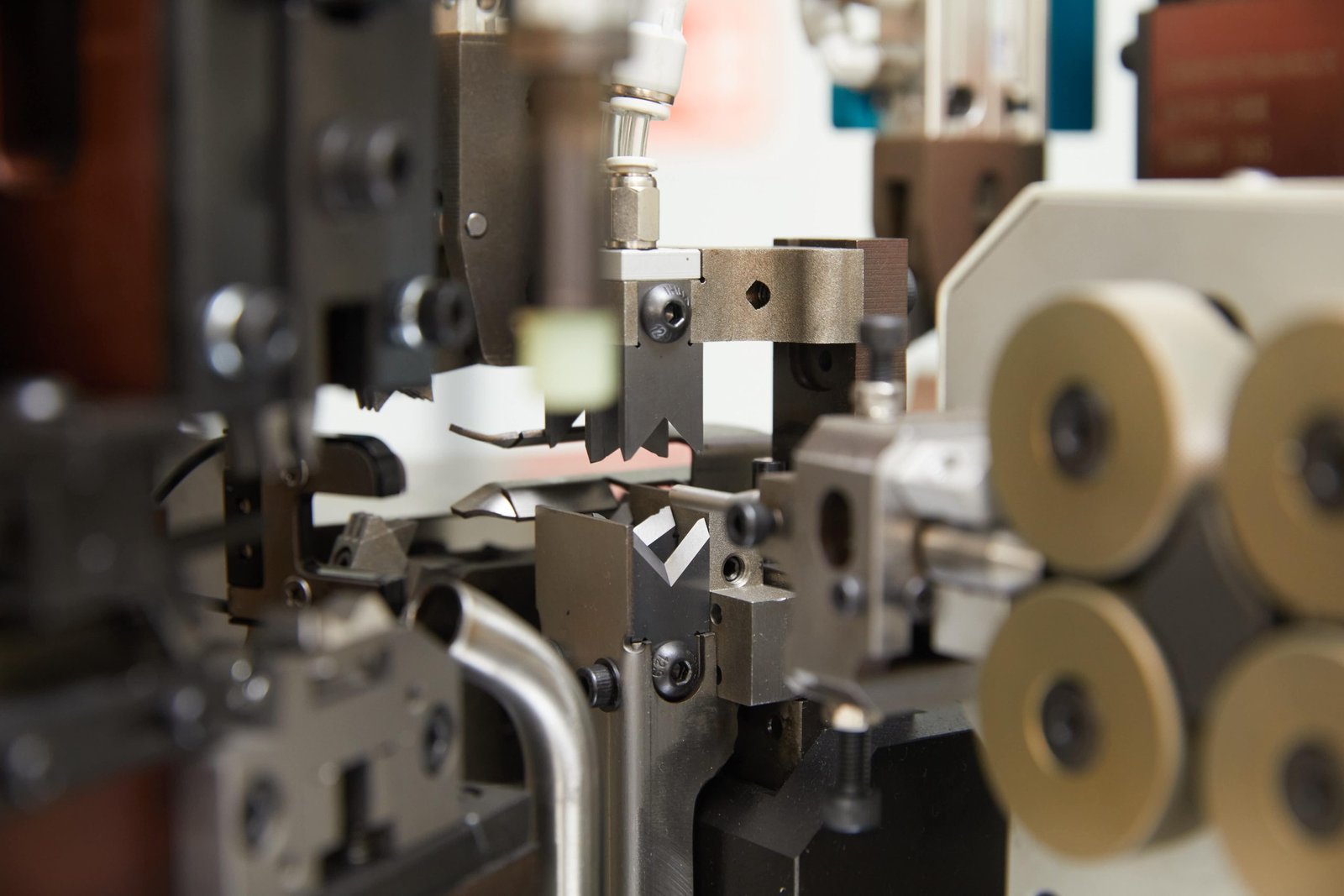

Crafted by Industry-Premier Professionals with Unmatched Precision, Every Machine Embodies Superiority

Automotive electrification/Smart appliance manufacturing/Medical device cabling/

Factory automation solutions/Aerospace wiring systems/Renewable energy infrastructure/

Next-gen consumer electronics

Kunshan Weijiang Automation Equipment Co., Ltd.

Precision Engineered Solutions for Wire Harness Processing

With 23 years of dedicated innovation andexcellence manufacturing excellence, Weijiang has established itself as the trusted industry leader and benchmark factory in wire harness processing equipment. Our comprehensive Weijiang System embodies this commitment, delivering meticulously engineered cut/strip machines, terminal crimpers, tape/winding machines, tube cutters, and inspection systems to meet the exacting demands of modern production environments.

Serving diverse industries from automotive to aerospace, medical devices to consumer electronics, we deeply understand each sector’s unique requirements. Our team collaborates closely with clients to deliver customized solutions that not only meet but frequently exceed production expectations. From initial consultation to after-sales support, we provide end-to-end service packages for every machine, designed to maximize operational uptime and production efficiency.

At our core lies an unwavering focus on quality – translating into durable, high-performance machines built to withstand continuous industrial operation. This quality-first philosophy is reinforced by our responsive service network, ensuring prompt technical and maintenance support when needed. While maintaining these rigorous standards, we’ve optimized manufacturing processes to deliver competitively priced solutions that achieve the lowest total cost without compromising reliability or performance.

Wire harness processing equipment is a key production system for electrical connectivity solutions, widely used across various modern industrial sectors. In the automotive industry, it manufactures vehicle wiring harnesses for both traditional fuel vehicles and new energy vehicles (NEVs), including high-voltage harnesses and charging systems. The electronics sector utilizes these machines to produce precision wiring for consumer electronics, home appliances, and industrial control devices.

The telecommunications industry relies on this equipment for specialized cables in 5G base stations, data centers, and networking hardware, while the aerospace sector demands ultra-reliable harnesses capable of withstanding extreme conditions.

Medical device manufacturing requires safety-compliant specialized wiring, and industrial automation/robotics applications need custom-designed harnesses with features like flex endurance and EMI resistance. The renewable energy sector (solar/wind power) and rail transportation (high-speed trains/subways) require processing capabilities for high-current, high-insulation cables. Additionally, smart home systems and LED lighting solutions depend on efficient wire harness production.

These systems perform critical processes including cutting, stripping, terminal crimping, assembly, and testing to meet diverse industry requirements for precision, reliability, and production efficiency. With the advancement of Industry 4.0, IoT, and clean energy technologies, wire harness processing equipment is evolving toward higher automation, intelligence, and flexibility to address future manufacturing demands.

The TSC – 1.5T series are an automatic high – speed silent wire stripping and crimping machine. It handles AWG36# – AWG14# wires, offers 1.5T crimp force, and integrates precise stripping and crimping. With low noise and energy use, it suits diverse manufacturing needs.

The BH-JD0, BH-JFS01, and BH-JF01 models are capable of fully automatic wire cable measure, cut, and wind. They support both wire roll and wire reel winding, ensuring efficient and versatile wire processing.

The TW – S35A is a lightweight, handheld adhesive tape winding machine. Its portable design enables easy operation in various scenarios, from electrical repairs to industrial maintenance and workholding pallet applications. Supporting multiple tape types, it offers flexibility for wire insulation, component securing, and surface protection, providing a convenient solution for diverse winding tasks.

The PC-A30 is specifically designed for cutting tubular materials such as corrugated pipes and rubber tubes. It boasts high efficiency and stable performance, ensuring that the cutting surfaces are smooth and flat. Each cut is executed with precision, reducing waste and enhancing productivity.

The CS-S41 is specifically engineered for precision processing of small to medium-sized wires, efficiently cutting and stripping insulation 0.1-4mm². Its advanced blade system ensures clean, smooth cuts without damaging copper conductors.

Wire harness processing equipment is a key production system for electrical connectivity solutions, widely used across various modern industrial sectors. In the automotive industry, it manufactures vehicle wiring harnesses for both traditional fuel vehicles and new energy vehicles (NEVs), including high-voltage harnesses and charging systems. The electronics sector utilizes these machines to produce precision wiring for consumer electronics, home appliances, and industrial control devices.

The telecommunications industry relies on this equipment for specialized cables in 5G base stations, data centers, and networking hardware, while the aerospace sector demands ultra-reliable harnesses capable of withstanding extreme conditions.

Medical device manufacturing requires safety-compliant specialized wiring, and industrial automation/robotics applications need custom-designed harnesses with features like flex endurance and EMI resistance. The renewable energy sector (solar/wind power) and rail transportation (high-speed trains/subways) require processing capabilities for high-current, high-insulation cables. Additionally, smart home systems and LED lighting solutions depend on efficient wire harness production.

These systems perform critical processes including cutting, stripping, terminal crimping, assembly, and testing to meet diverse industry requirements for precision, reliability, and production efficiency. With the advancement of Industry 4.0, IoT, and clean energy technologies, wire harness processing equipment is evolving toward higher automation, intelligence, and flexibility to address future manufacturing demands.

We will update New products, New functions, Machine upgrade, Important company news, Promotion and so on.

WEIJIANG manufactures wire stripping machines, terminal machines, pipe cutting machines, winding machines, welding machines, tape wrapping machines, etc., and provides customers with one-stop wire harness solutions. We will continuously update new products, technologies, functions, and the latest information about the company. Welcome to consult WEIJIANG for more information.

Cables are used in everything around us—from home electronics to large machines. But before cables can be used, they must be safe, neat, and strong.

In today’s fast-moving world, machines help us work faster and better. One such tool is the automatic wire cutting and stripping machine. This machine is

To learn about Wire Harness Machine Manufacturer New Products, Machine Upgrades, Promotions, and more! Welcome to subscribe here!

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions