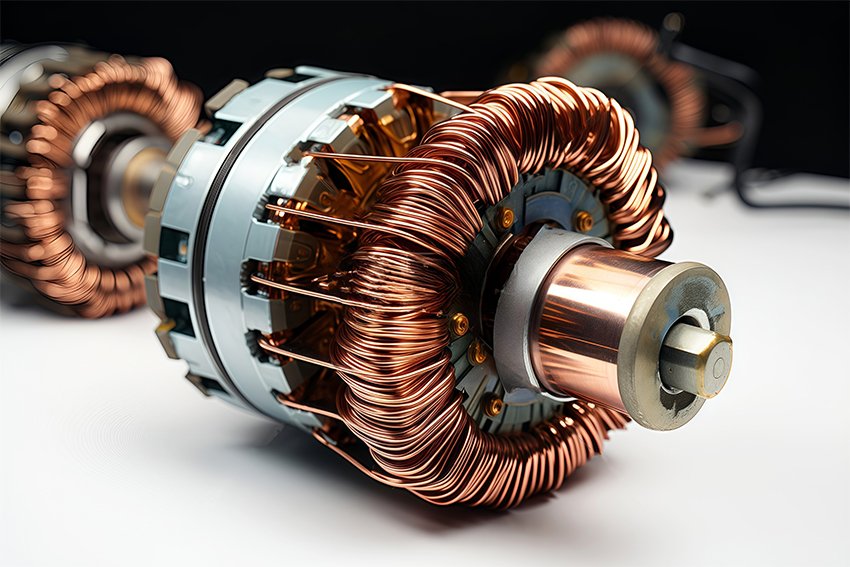

The BH-NL003 is a dedicated nylon cable tie machine for motor stators. With support for multiple cable tie sizes, it ensures precise bundling.

Exclusive Motor Stator Focus

The BH-NL003 is engineered with a single – minded purpose: to handle the intricate task of nylon cable tying for motor stators. This dedicated design ensures that every aspect of its functionality is optimized for the unique requirements of stator wire bundling. By eliminating the need to adapt to other applications, it delivers unrivaled precision and efficiency in stator production, reducing the risk of errors that could occur with multi – purpose machines.

Versatile Cable Tie Compatibility

It supports a diverse range of cable tie sizes, including 2.580mm, 2.8100mm, 2.5120mm, 2.5150mm, and 3150mm. This variety allows for precise bundling of different wire gauges and stator designs. For example, thinner ties like 2.580mm can be used for small – scale stators with delicate wiring, while larger 3*150mm ties are ideal for heavy – duty stators with thick, multiple – strand cables. This adaptability ensures that the machine can meet the needs of various motor stator manufacturing processes.

Efficient and Stable Power Operation

Operating at 100W power, the BH-NL003 provides sufficient energy for consistent and reliable performance. It is compatible with both AC 220V and 110V power supplies at 50/60Hz frequencies, making it suitable for use in different regions around the world. This wide – ranging power compatibility ensures seamless integration into global motor manufacturing facilities without the need for complex power conversion equipment, allowing for continuous and stable operation during stator production.

Precision Tying for Stator Integrity

The machine is designed to apply the perfect amount of tension when securing nylon cable ties around motor stator wires. This precise tying not only keeps the wires organized but also protects them from damage during handling, transportation, and operation of the motor. By maintaining the integrity of the wire arrangement, the BH-NL003 contributes to the overall efficiency and longevity of the motor stator, reducing the likelihood of electrical failures caused by loose or damaged wires.

Compact and Sturdy Design

With dimensions of 606072cm and weighing 150kgs, the BH-NL003 offers a compact yet robust structure. Its small footprint makes it suitable for installation in various manufacturing environments, even those with limited space, such as smaller workshops or densely – populated production lines. The sturdy construction ensures stability during operation, minimizing vibrations that could affect the accuracy of the cable tying process. This combination of compactness and durability allows for easy integration into existing stator production setups.

User – Friendly Operation

Despite its specialized function, the BH-NL003 is designed with user convenience in mind. The control interface is intuitive, allowing operators to quickly select the appropriate cable tie size and adjust other relevant settings. Clear indicators and safety features are incorporated to ensure safe and efficient operation. Training new operators on this machine is straightforward, reducing the time and cost associated with staff training and enabling seamless onboarding into stator production processes.

Low – Maintenance and Long – Lasting

Built with high – quality materials and components, the BH-NL003 is engineered for durability. Its dedicated design for motor stators means that the internal mechanisms are optimized for this specific task, reducing wear and tear. Routine maintenance is simplified, with easily accessible parts for inspection and replacement. This low – maintenance design not only minimizes production downtime but also reduces long – term operating costs, making it a cost – effective investment for motor manufacturing companies.

Enhanced Production Consistency

By focusing solely on motor stator cable tying, the BH-NL003 ensures high levels of production consistency. Each stator that passes through the machine receives the same level of precision and quality in cable bundling. This consistency is crucial for meeting strict manufacturing standards and for the reliable performance of the motors in which these stators are installed. It also streamlines quality control processes, as the predictable output of the machine makes it easier to identify and address any potential issues.

| Model | BH-NL003 |

| Cable tie size | 2.5*80mm/2.8*100mm/2.5*120mm/2.5*150mm/3*150mm |

| Power | Power:100W |

| Power supply | AC 220/110V/50/60Hz |

| Size | 60*60*72cm |

| Weight | 150kgs |

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to wj3@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions