The CW – BU120 ultrasonic tape/label cutting machine utilizes advanced ultrasonic technology to achieve rapid and precise cutting. Its high – frequency vibrations enable smooth, burr – free cuts on a wide range of tapes, ensuring superior edge quality. With a compact design and user – friendly operation, this machine offers reliable performance and high efficiency, making it an excellent choice for tape/label cutting tasks.

CW-BU120 Features:

1. Ultrasonic cutting, complete and beautiful incision, neat and smooth cutting edge, no rough edge, no loose edge, excellent cutting effect

2. This machine adopts PLC control console to automatically feed, computer counting, high precision, fast speed, arbitrary length and Angle adjustment, automatic cutting, efficient and fast, beautiful and efficient cut, and can be cut at many times at the same time

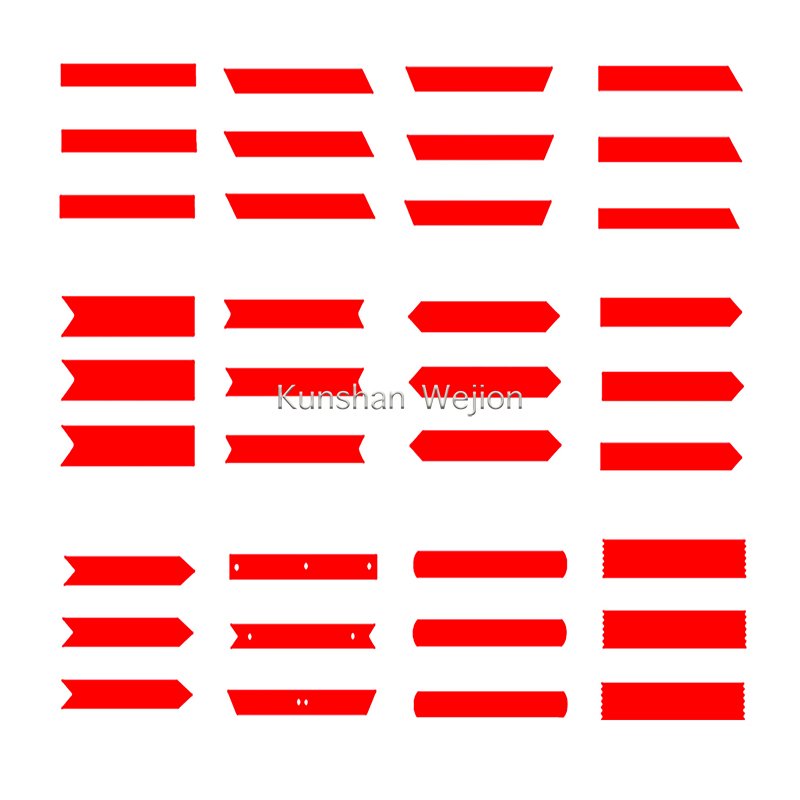

3.It is mainly used for gift belt, strip nylon belt, strip ribbon cutting straight knife, oblique knife, swallowtail and other shapes

4. The frequency and power of ultrasonic machine are determined by cutting the ribbon

5. Used in & have spent Program-controlled ultrasonic cutting machine in ribbon industry

6. The cut ribbon section does not change color, automatic sealing, no burr

7. The stepper motor drive is controlled by a special integrated circuit, and the length of strip cutting, the speed of strip cutting and the number of continuous strip cutting can be designed in advance.

| Model | CW-BU120 |

| Cutting length | 1-99999mm |

| Max cut width | 100mm |

| Cut speed | 100-120pcs/min |

| Power supply | 220/110V,50-60Hz |

| Power | 1500W |

| Size | 80*60*100cm |

| Weight | 80kgs |

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to wj3@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions