The telecommunications industry connects people across the world. From phone calls to internet services, it keeps us linked every day. Behind this huge network lies a complex system of cables and connections. One important part of this system is the telecommunication wire harness.

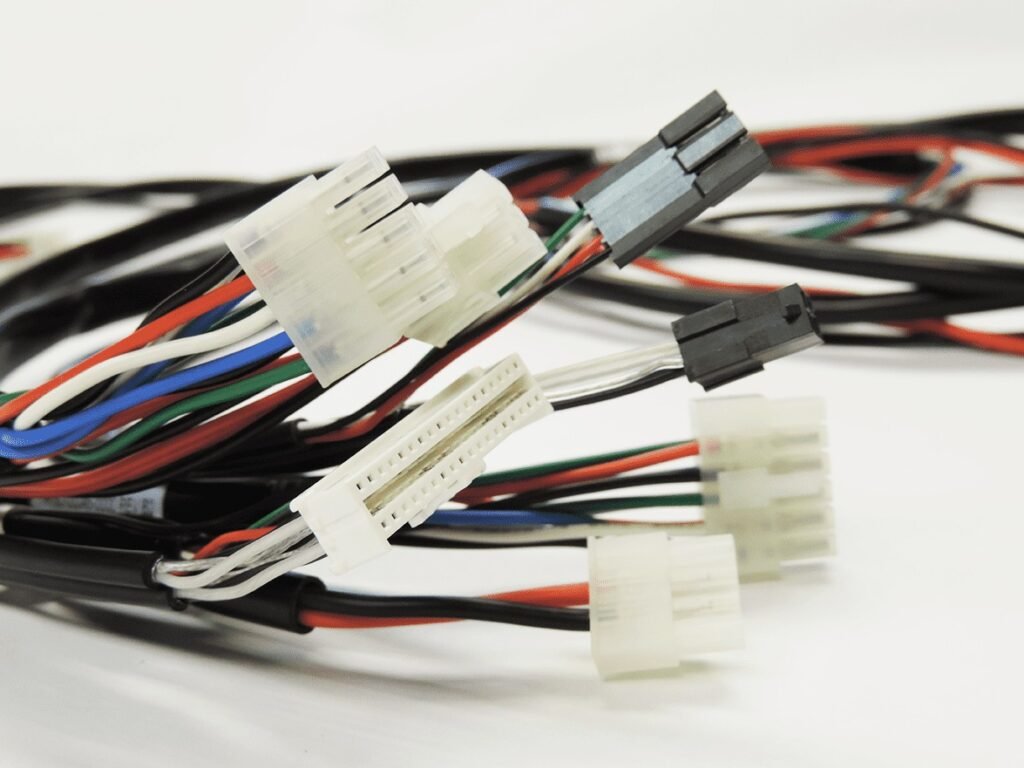

A wire harness is a group of wires bundled together with protective coverings and connectors. It allows power and signals to travel safely and efficiently. In telecommunications, these telecom wiring harness assemblies make sure that communication equipment works smoothly without interruptions.

At Kunshan Automation Co., Ltd, specialise in offering advanced wire processing and harness assembly machines and solutions. Our technology helps produce high-quality telecommunication wire harnesses that meet the strict demands of the telecommunications industry.

Benefits of Wire Harnesses in the Telecommunications Industry

Wire harnesses play a vital role in preserving telecommunications structures. One of the primary advantages is the employer. A harness continues wires neatly, which prevents tangles and damage. This is critical in telecom devices in which masses of cables may be used.

Safety is the only benefit. The protective shields protect wires from moisture, dust, and heat. This reduces the threat of quick circuits and ensures the device lasts longer. In outside telecom setups, the harness can also defend against climate harm like rain or strong sunlight.

Data transmission cable harness also enhances performance. By retaining cables securely in place, they reduce sign interference. This manner calls for clearer, quicker internet, and fewer dropped connections. For telecom groups, this reliability builds trust with clients.

Harnesses make renovation easier. If there’s a hassle, technicians can quickly update the harness in preference to spending hours sorting through unfastened wires. This saves time and decreases provider interruptions.

Our Telecommunications Wire Harness Manufacturing Process

We observe a detailed process to ensure each telecommunication wire harness meets industry standards.

We start with the know-how and the task necessities. We have a look at the telecom gadget’s design, the form of indicators it consists of, and the environmental situations it’s going to face. This facilitates us in choosing the proper wire kinds, lengths, and shielding substances.

Next, we use precision wire processing machines to cut the wires to actual lengths. We strip insulation from the ends and fasten super connectors. These connectors are crucial for easy electricity and signal transmission.

After that, we package the wires together in a prepared manner. We use long-lasting sleeves, tubing, or tape to guard them. For outdoor telecom packages, we upload extra climate-resistant substances.

Before shipping, each harness goes through strict testing. We test for correct wiring, proper connections, and sign overall performance. This guarantees the harness works flawlessly earlier than it’s installed on your telecom gadget.

Types of Telecommunications Wire Harnesses

The telecommunications industry uses different styles of wire harnesses depending on the application.

One type is the indoor telecom harness, which is used on top of things like rooms, server racks, and workplace communication structures. These harnesses are typically smaller and designed for solid indoor environments.

Another kind is the outdoor telecom harness. These are constructed to face up to weather modifications, UV rays, and moisture. Outdoor telecom wire harness designs are regularly used for mobile towers, satellite structures, and outdoor network bins.

We also make fiber optic cable harnesses, which can be vital for high-velocity net connections. These harnesses require greater care to save you from damage to the delicate fibers inside.

In a few cases, telecom businesses need custom harnesses. These might also encompass mixed strength and information cables, unique connectors, or unique defensive coverings. At Kunshan Automation Co., our machines and professional group can create those custom telecommunication wire harnesses with precision.

Challenges in Telecommunications Wire Harness Manufacturing

Making a telecommunication wire harness for telecom structures comes with demanding situations. One of the most important is accuracy. Even one out-of-place wire can disrupt conversation signals. That’s why we use advanced wire processing machines to cut and put together wires with precision.

Another task is durability. Telecom equipment frequently runs 24/7. The harness has to manage constant use without wearing out quickly. This means the usage of strong materials and high-quality connectors.

The complexity of telecom networks adds another mission. Many harnesses want to healthy into tight spaces even as connecting a couple of gadgets. Designing these harnesses calls for ability and interest in detail.

There is likewise the issue of environmental safety. Outdoor telecom harnesses must survive high temperatures, rain, and wind. Choosing the wrong protective fabric can lead to failures.

Keeping up with generation adjustments is essential. As telecom structures grow to be quicker and more sophisticated, harness designs must adapt. This calls for ongoing innovation and investment in modern production gear.

Telecommunications Wiring Harness Market Trends

The marketplace for telecommunication wire harnesses is growing rapidly. This is because of the worldwide demand for quicker internet, higher cellular coverage, and extra related devices.

One trend is the usage of fiber optic harnesses. With the upward thrust of 5G and high-speed broadband, telecom groups are shifting closer to fiber networks. These require special harnesses that protect sensitive fiber cables while also keeping them prepared.

Another fashion is miniaturisation. Telecom devices are getting smaller; because of this, harnesses should fit into tighter areas without dropping overall performance.

There’s also a focal point on green materials. Many agencies are looking for efficient network infrastructure wiring systems that also offer sturdy protection. This aligns with the worldwide push for sustainable products.

Get the expert custom communication equipment wiring solutions

In the quick-paced telecommunications industry, having reliable wiring structures is crucial. At Kunshan Weijiang Automation Equipment Co., Ltd, we provide expert machines and custom telecom cable assemblies for producing exceptional.

Whether you want preferred harnesses or custom designs, our device can handle the job. We assist telecom companies in creating safe, green, and sturdy wiring structures that keep networks going for walks smoothly.

Our group works carefully with customers to understand their desires. We then use our cutting-edge machines to supply harnesses that meet strict industry standards. With our solutions, you may reduce production time, enhance product excellence, and ensure long-lasting overall performance.

Choosing our approach to getting more than simply machines. You get a reliable accomplice with years of experience in wire harness production. We are devoted to assisting you in constructing reliable telecommunication wire harnesses that keep people connected, everywhere in the global.