Home appliances and lights are part of our daily life. We use refrigerators, washing machines, ovens, fans, and lights every day. But have you ever thought about how they work safely? The secret is the home appliance wire harness.

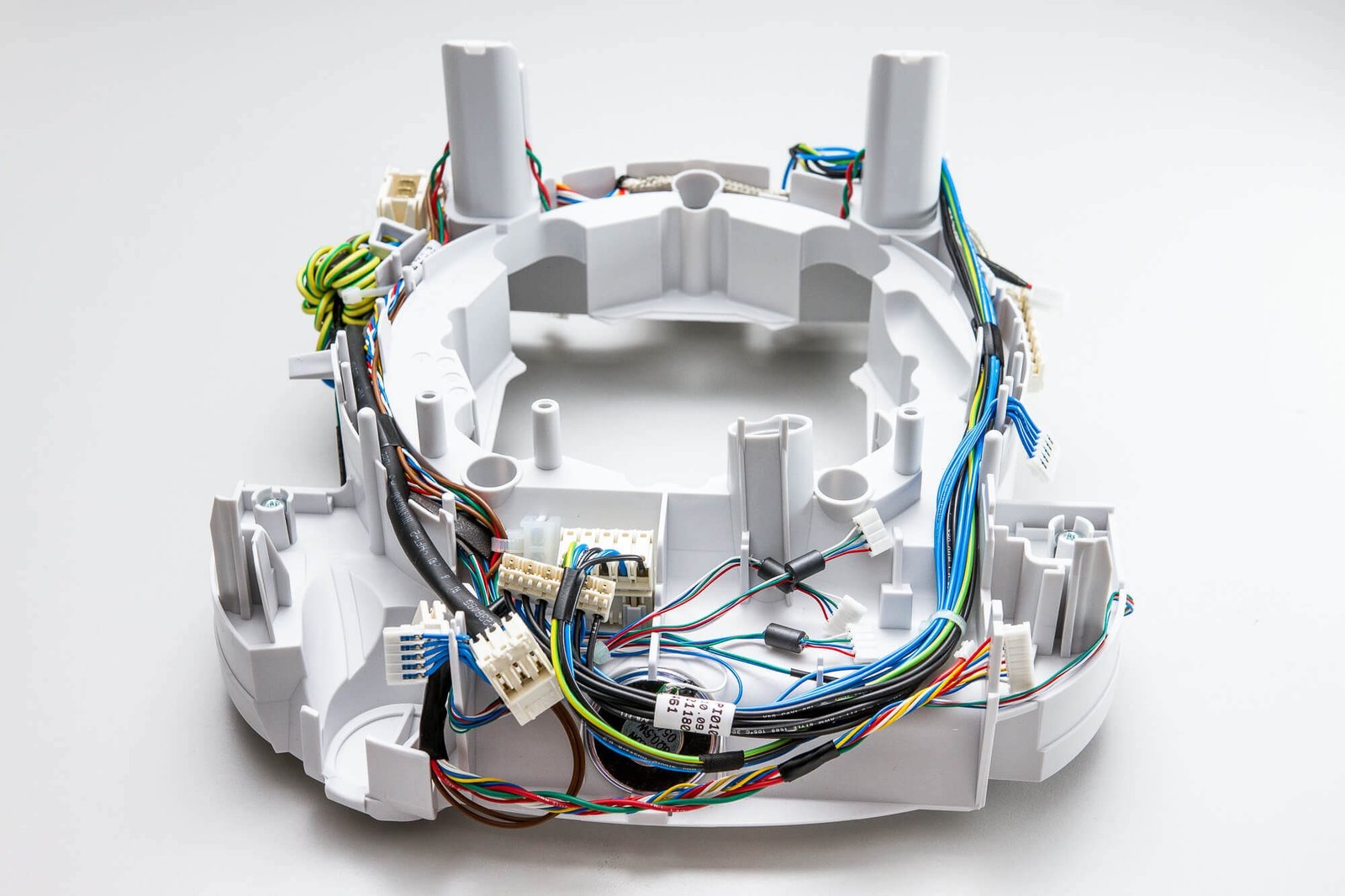

A wire harness is a group of wires tied together to carry electricity and signals. It connects the different parts inside an appliance or light. Without it, nothing would run properly. A good harness keeps electricity flowing smoothly, makes products safe, and helps them last longer.

Making these home appliance wire harnesses is a special job. It needs care, modern machines, and expert knowledge. This is where Kunshan Weijiang Automation Company comes in. They offer advanced machines for wire processing and harness assembly. With their help, manufacturers in the home appliance and lighting industry can build safe, strong, and high-quality harnesses.

Household wiring harness assembly may look simple, but it brings many benefits to appliances and lights.

The first benefit is security. Tools such as ovens, microwave and washing machines use too much electricity. If the wires are loose or dirty, it can cause small circuits, sparks or even fire. A strong wire harness keeps wires organised and safe.

The second benefit is efficiency. A harness bundles the wires neatly, so workers can install them rapidly in the factory. It saves time and low cost. For lighting, it means stable power so that the light shines without flicker.

The third benefit is durability. Tools such as refrigerators or dishwashers last for many years. A good harness can handle heat, cold, vibration and moisture. For lights, a harness ensures that the system works for a long time and uses low energy.

Another big benefit is quality control. When manufacturers use proper home appliance wire harness services, the products meet global safety standards. This builds customer trust and avoids expensive product recalls.

Making a wire harness for appliances and lights is not just about tying wires. It is a step-by-step process that must be done correctly.

It all begins with the design. Engineers decide how many wires are needed, what type of wires to use, and where each one should connect.

Then comes wire cutting and stripping. Wires are cut to exact lengths. The insulation is carefully removed from the ends so the wires are ready for connectors. With the help of Kunshan Weijiang Automation Company’s advanced machines, this step is fast, clean, and accurate.

Next, the wires are assembled on a harness board. The wires are laid out in the right positions. Connectors, clips, and terminals are added. This step makes sure every wire goes to the correct place.

After assembly, the kitchen appliance cable harness is wrapped and protected. Tapes, tubes, or sleeves are used to cover the wires. This keeps them safe from heat, water, and wear.

Finally, each harness is tested. Special machines check the flow of electricity, insulation strength, and performance. Only harnesses that pass these tests are used in appliances and lighting products.

Wire harnesses are not the same for every product. Each home appliance needs a special type of wire harness to match its function, power use, and working environment. Let’s look at the main types.

Refrigerators and freezers need harnesses that work well in cold and moist conditions. These refrigerator wiring harness solutions use strong insulation to prevent water damage. They also keep the current flow stable so the cooling system runs smoothly for years.

Washing machines and dryers create heavy vibration and deal with water every day. Their electrical harness for washing machines is built tough to handle shaking and moisture. They also carry enough power to run motors, pumps, and control systems without failure.

Ovens, microwaves, and induction cookers create high heat. That is why their harnesses use heat-resistant wires and connectors. These kitchen appliance cable harnesses are designed to stay safe even when exposed to extreme temperatures during cooking.

Air conditioners and heaters need harnesses that can handle heavy electrical loads. These harnesses connect compressors, fans, sensors, and controllers. They must stay safe while running for long hours in both hot and cold conditions.

Lighting harnesses are usually designed for low-voltage power. In LED and smart lighting systems, the small appliance cable assemblies ensure stable current flow to avoid flickering. Many modern lighting harnesses also carry data signals for smart controls, dimmers, and sensors.

Even though home appliance wire harnesses are common, they come with challenges.

A challenge is a complex design. Modern equipment is not simple. He has smart features, digital displays and sensors. This means more wires and more connections.

Another challenge is the safety rule. Since these products are used at home every day, they should follow strict safety standards. If the harness is made poorly, it can cause accidents.

The third challenge is the environment. Heaters for the oven face heat, they face water for the washing machine, and they face cold for the refrigerator. It is very important to choose the right material.

The final challenge is the pace of production. It takes time to make a harness by hand and may cause mistakes. This is why the producers turn to the Kunshan Weijiang Automation Company. Their advanced machines make the process fast, safe and more accurate.

The home appliance wire harness market for home appliances and lights is growing quickly. The main reason is the rise of smart homes and energy-saving products.

People now want tools that are smart, safe and skilled. Refrigerators, washing machines, air conditioners and ovens all require an advanced wiring harness. Energy-saving models require even more careful harness design to reduce electricity loss.

The light market is also changing. LED lights and smart lighting are replacing traditional bulbs. These new systems require a precise wiring harness to connect sensors, demersals and smart control. With the rise of the Internet of Things (IOT), Harnes should carry both electricity and data.

Experts say that the demand for wiring harnesses in equipment and lighting will continue to increase for years. Like the Kunshan Weijiang Automation Company, companies using advanced automation solutions will be ready for this development and will be ahead of the competition.

No two appliances are the same. Each product needs a unique home electronics wiring solution. This is why custom solutions are so important.

For example, a refrigerator needs a harness that works well in moisture. A microwave needs a harness that can withstand heat. A smart lighting system needs a harness for both power and control signals. Using the same harness for all would not work.

With the help of Kunshan Weijiang Automation Equipment Co., Ltd, manufacturers can create custom harnesses easily. Their wire processing and harness assembly machines can be adjusted for different designs. This allows fast and accurate production for every kind of appliance or light.

Custom solutions mean better safety, better efficiency, and better product life. They also make sure the final products meet international safety standards. When companies use professional machines for custom home appliance wire harnesses, they save time, cut costs, and improve quality.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions