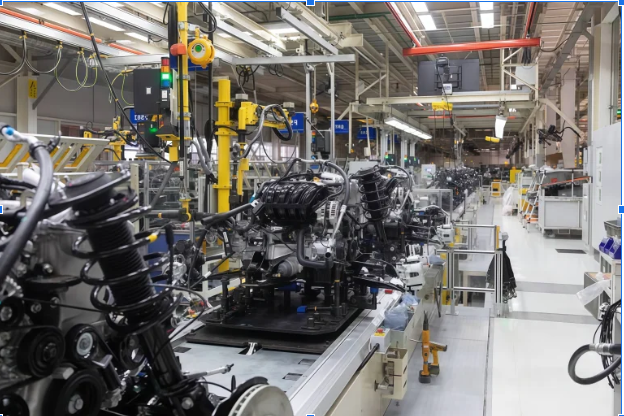

Cars today are more advanced than ever. They have smart safety systems, powerful infotainment setups, and even self-driving features. Behind all these technologies, there is one hidden hero- the automotive wire harness. The vehicle wiring system comprises a set of wires, connectors, and protective coverings that transmit power and signals to various components of a car. Without it, none of the lights, sensors, or electronics would work.

Automotive Wire Harness Manufacturing is not just about putting wires together. It is a detailed process that demands precision, quality, and compliance with automotive standards. At Kunshan Weijiang Automation Equipment Co., Ltd, we provide wire processing and harness assembly machines that make this process faster, more accurate, and more reliable for manufacturers.

Importance of Wire Harnesses in the Automotive Industry

A car has hundreds of electrical connections. These connections include electricity, headlights, airbags, engines, and entertainment systems. An automotive wire harness continues some of these wires, prepared and protected. It prevents tangling, reduces the risk of electrical faults, and makes set-up less complicated.

In the car industry, protection is continually the top priority. Wire harnesses play a huge role in safety structures, which include ABS brakes, airbags, and collision sensors. They make sure those structures work immediately when needed. A faulty harness can cause a postponement or failure, which might be risky.

For electric cars (EVs), the importance is even greater. The engine wiring harness should convey high voltage adequately while being lightweight to enhance battery performance. In this manner, the materials and design have to meet strict requirements.

Our Automotive Wire Harness Manufacturing Procedure

We understand that satisfaction begins with the right automotive wire harness manufacturing method. Our wire processing and harness assembly machines are designed to make every step speedy, precise, and consistent.

The method starts with design and engineering. Each harness is the result of deliberate CAD software usage. This ensures the wires are cut to the precise length and routed efficiently. Every design is tailored to the car’s specific needs, whether it’s for a passenger automobile, truck, or electric car.

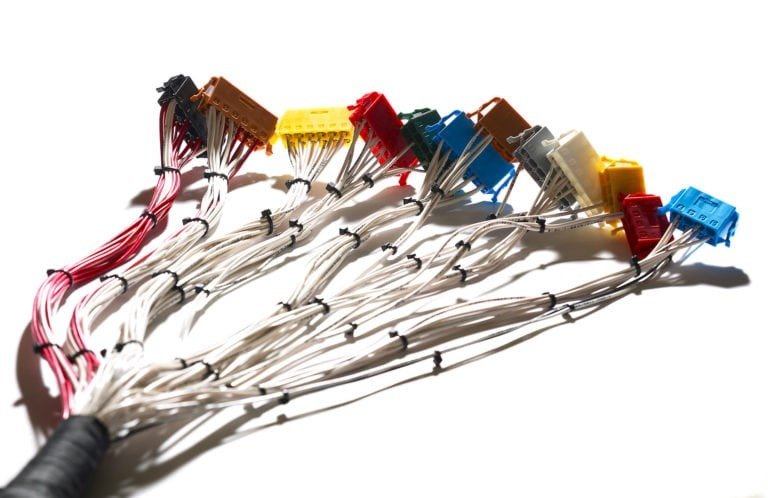

Next comes fabric selection. We use wires, insulation, and connectors that meet international automotive standards like ISO and IATF 16949. This ensures durability in opposition to heat, vibration, and moisture.

We then flow to reducing, stripping, and crimping. Our high-velocity machines cut every wire to period, strip the insulation, and crimp the terminals. Automation makes these steps extra correct and quicker than guide work.

Once prepared, wires go through a meeting and bundling. The wires are arranged according to the design, secured with protective tubes or tapes, and organised into bundles.

Finally, we carry out a trial and pleasant manipulation. Each harness is checked for electrical continuity, resistance, and energy. We also run durability checks to ensure they work flawlessly even under intense conditions.

Types of Automotive Wire Harnesses

Different automotive electrical components of an automobile require extraordinary harnesses. We design and manufacture machines for almost all the most important types used inside the automobile industry.

The engine wire harness connects sensors, fuel injectors, and ignition systems to the engine management unit. This harness should resist high heat and vibration.

The lighting fixtures’ wire harness powers headlights, taillights, and indicators. It ensures the motive force can be definitely and be visible by using others.

The dashboard and infotainment harness connect the speedometer, touchscreens, and audio systems. It contains both power and statistics indicators for easy operation.

The battery and EV harness are particularly made for electric and hybrid cars. It incorporates high-voltage electricity from the battery to the motor whilst ensuring protection.

The safety machine harness connects airbags, ABS brakes, and different shielding features. It ought to work immediately in emergencies.

Challenges in Automotive Wire Harness Manufacturing

The automotive industry is converting fast. New technology, environmental policies, and client demands convey challenges to wire harness production.

One project is increasing in complexity. Modern automobiles, in particular EVs and independent cars, require more wires, sensors, and control devices. This method harnesses are larger and extra complex than ever.

Another trouble is warmth and vibration resistance. Harnesses need to continue to exist for years of use in harsh situations without harm. This requires better substances and precise manufacturing.

Space is likewise an undertaking. Cars nowadays are designed to be compact, leaving much less room for wiring. Harnesses must be lightweight and fit into tight spaces without affecting overall performance.

There are costs and delivery chain pressures. The price of copper, plastics, and connectors can trade speedy. Manufacturers should balance exceptional quality nd price to stay competitive.

Automotive Wiring Harness Market Insights

The name for car wire harnesses is growing internationally. This boom is driven by way of the upward thrust of electric automobiles, hybrid technology, and smart motors. According to industry research, the worldwide automotive cable assembly market is predicted to grow steadily over the next decade.

Electric cars require more vehicle wiring loom than conventional automobiles. This way more opportunities for harness manufacturers, but also greater pressure to supply extraordinary products speedily. Advanced protection systems like ADAS (Advanced Driver Assistance Systems) and infotainment capabilities are also increasing wiring needs.

In many countries, strict safety and emission rules are pushing automakers to use better materials and designs. This increases the need for automated manufacturing answers just like the ones we offer.

Contact the trusted Wire Harness manufacturer

When it involves finding a dependable accomplice for automotive wire harness production, you want someone familiar with both the demanding situations and possibilities of the car industry. Kunshan Weijiang Automation Equipment Co., Ltd is one such trusted name.

We focus on wire processing and harness assembly machines that assist producers in producing notable harnesses faster and greater effectively. Our machines deal with everything from cutting and stripping to crimping, assembly, and testing.

We are committed to the best, innovation, and client satisfaction. Our solutions are utilised by leading automobile harness producers around the world. Whether you’re producing harnesses for conventional motors, electric cars, or heavy-duty trucks, our device ensures precision, sturdiness, and compliance with international standards.

Choosing the proper accomplice approach is more than just getting the proper car wiring connector system. It way getting the proper guide, education, and expertise. We work closely with our customers to make certain they have the whole lot they need for fulfilment.