35mm² Industrial Cable Stripper,Heavy-duty wire stripping machine for 4-35mm² (AWG 2) power cables, handles 3-16mm thick XLPE/PVC insulation with 1500N cutting force. auto centering, and adjustable 0.1-250mm strip length. Ideal for substations, wind farms, and industrial power distribution. CE/UL certified with IP54 protection.

WJ-835 wire stripping machine is an efficient stripping equipment for high current and large-size cables (such as 35 square cables). It adopts modular design to optimize the performance of each component to ensure efficient, accurate and stable stripping operation. It is particularly suitable for industrial occasions that require high stripping accuracy and large-scale processing.

Function & Features

1. Modular design

* The modular design principle makes the structure of the whole machine more compact and reasonable, and convenient for maintenance and upgrading.

* Different processing requirements can be met by replacing different modules, which improves the flexibility and scalability of the equipment.

2. Precision gearbox

* Four sets of precision guide components and high-precision ball screws are used, and all guide accessories are precisely ground to ensure the accuracy of the guide.

* With the precise transmission system, the equipment can be stably operated in long-term use, with a long service life, which greatly reduces the frequency of repair and maintenance.

3. Dual motor wire feeding system

* The upper and lower wire feeding are controlled by dual motors separately, which greatly improves the accuracy and stability of wire feeding and reduces the stripping error caused by uneven wire feeding.

*The dual motor system can adjust the speed and strength according to different wire materials and different processing requirements to ensure more uniform wire feeding.

4. Hard knurled synchronous wheel

*The wire feeding synchronous wheel adopts hard knurling treatment, which improves the wear resistance and anti-slip ability, ensuring that it is not easy to wear during long-term use.

*The knurling design enhances the contact effect between the synchronous wheel and the cable, effectively avoids slipping, and improves the accuracy and stability of wire feeding.

5. Tool holder design

*Hard rail guide tool holder design: It has the advantages of small size, low noise, stable operation, and long service life, ensuring high precision and low noise during the stripping process.

*Large speed planetary reducer: Improves the stripping accuracy, reduces noise and vibration, and the strong cutting torque can meet the stripping requirements of large diameter cables.

*High-strength reinforced blade: The blade is made of wear-resistant material, has a long service life, and reduces the frequency of blade replacement.

6. Straightening frame

*The wire pressing wheel adopts a double-row ball-in-one U-shaped wheel, which can effectively stabilize the wire, ensure that the wire will not bend or skew during the stripping process, and extend the service life.

*The wire entry hole uses high-quality ceramic eyes to avoid damage to the cable and has extremely high durability.

*Double-section design: The tightness of the front and rear parts can be adjusted separately to ensure better straightening effect and avoid knotting or deviation of the wire during processing.

7. High efficiency and high precision

*The overall design ensures high efficiency and high precision, which is suitable for stripping of high-current cables, especially the stripping requirements of large-size wires such as 35 square cables.

*Low noise design: The overall design takes into account the noise control during equipment operation and provides a quieter working environment.

Application areas

1. Power and cable industry:

* Mainly used for stripping of large-size cables such as power cables, high-voltage cables, and power cables.

* In the fields of power transmission and distribution systems, distribution cables, power facilities, etc., it can provide efficient and precise stripping solutions.

2. New energy industry:

* Especially suitable for the processing of new energy vehicle cables such as new energy charging pile wiring harnesses, electric vehicle cables, and high-voltage shielded wires.

* It can handle new energy high-voltage cables and meet the cable processing needs in the fields of electric vehicles, solar energy, wind energy, etc.

3. Industrial manufacturing and automation equipment:

* In the production process of automation equipment, it can provide high-precision stripping for robot cables, industrial transmission lines, etc.

* Suitable for batch processing of various industrial cables.

4. Shipbuilding and aerospace industry:

* It can handle ship cables, aircraft cables, etc., and is suitable for cable stripping needs in some special environments, ensuring high precision and durability.

* Power and communication facilities:

* For the processing of power communication cables (such as communication cables, optical fiber cables, etc.), WJ-825 provides efficient and accurate stripping processing to ensure product quality and production efficiency.

5. Automobile manufacturing industry:

* In the manufacturing of automotive wiring harnesses, WJ-825 can effectively process the wiring harnesses of electric vehicles and traditional vehicles to ensure processing accuracy.

6. Home appliance industry:

* Used for stripping processing of home appliance cables and household appliance cables to ensure the accuracy and safety of wire adapter connections.

| Model | WJ-835 | |

| Cutting diameter | 3-16mm | |

| Wire range | 4-35mm² | |

| Cutting length | 0.1mm-99999.9mm | |

| Stripping length | Stripping head:0.1-250mm Stripping tail: 0.1-70mm | |

| Tube diameter | 4/6/8/10/12/14/16mm | |

| Wire feeding speed | 40-50 meter/minute | |

| Capacity | 900-1300 / h | |

| Blade material | Imported tungsten steel / high speed steel | |

| Voltage | AC110V/220V 50/60HZ | |

| Dimension | 65 * 58 * 46cm | |

| Weight | 95kg | |

| Remark function | Automatic entry / exit, timing start, jog adjustment | |

| Power | 1.8KW | |

| Air supply | 0.5-0.7Mpa | |

| Model | WJ-835 |

|---|---|

| Cutting diameter | 3-16mm |

| Wire range | 4-35mm² |

| Cutting length | 0.1mm-99999.9mm |

| Stripping length | Stripping head:0.1-250mm Stripping tail: 0.1-70mm |

| Tube diameter | 4/6/8/10/12/14/16mm |

| Wire feeding speed | 40-50 meter/minute |

| Capacity | 900-1300 / h |

| Blade material | Imported tungsten steel / high speed steel |

| Voltage | AC110V/220V 50/60HZ |

| Dimension | 65 * 58 * 46cm |

| Weight | 95kg |

| Remark function | Automatic entry / exit, timing start, jog adjustment |

| Power | 1.8KW |

| Air supply | 0.5-0.7Mpa |

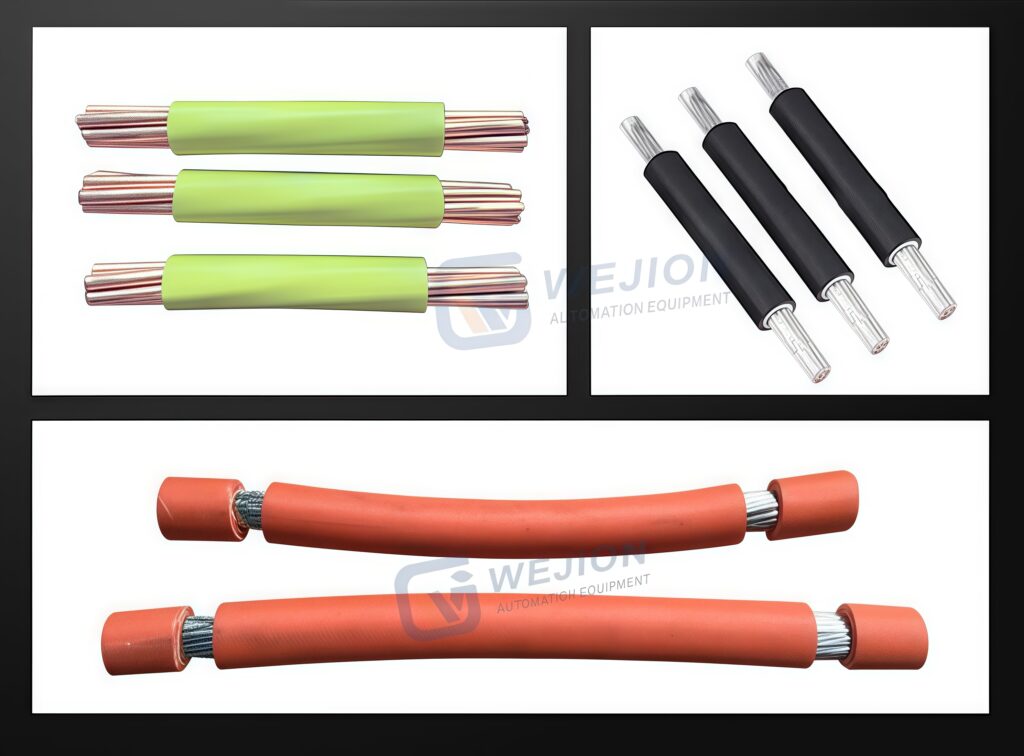

35mm² Cable Applications

Safety Warning:

If you wish to have the datasheet of this or other products, you can let us know here: CONTACT

Or email to wj3@ksweijiang.com, we will send you the machine introduction.

If you hope to inquiry just this product, please send a message here. If you hope to inquiry several products, please Add To Quote, quote all products on the Request Quote page.

© Copyright 2015 – 2025WEJION. All rights reserved.

© 2025 WEJION. All rights reserved. Privacy Policy | Terms and Conditions