Semi automatic terminal crimping machines are strong and reliable tools that many businesses use every day. Employees can connect cables and terminals more easily and safely with it. The machine keeps a steady pressure with every push. This makes sure that every crimp looks the same. It also helps the crimps stay tight for a long time. This device makes it less likely for people to make mistakes. It speeds up the work every day. It is easy to use. You can learn it quickly. New employees will learn it quickly.

The older workers trust it completely. It’s simple to use for small workshops. It is also important for big factories. As a dependable semi auto crimping machine supplier, many manufacturers now put safety, longevity, and ease of use first. This makes the machine a safe and smart choice for modern wiring jobs.

Industrial Accuracy in Crimping Work

When crimping wires, you need to be very careful. Small mistakes can cause big problems later on. Exact crimps keep cables safe. Accurate crimps keep the power flow steady. An inadequate crimp could cause heat to build up. There may be sparks. Wires may get damaged. A good crimp keeps these dangers from happening in the first place. The Semi Automatic Electric Terminal Crimping Machine always applies the same amount of force. This force stays the same all day. So, the quality of the product stays good.

This Semi Automatic Terminal Crimping Machine also means that less material is wasted. Costs go down because there is less waste. Workers are less stressed. They feel like they’ve done more. Production goes smoothly all day long. That’s why many factories have stopped using manual tools and started using semi-automatic ones instead.

Core Benefits of Semi Automatic Crimping Technology

Using a semi auto crimping machine in daily operations has a number of obvious benefits. The rate of production is steadily going up. The stability of output gets better. The error rate goes down quickly. The quality stays good. New employees don’t have many chances to learn the ropes.

The computer works with different kinds of terminals. It works great with copper wire. Aluminum wire also works. Every time you push, the pressure stays the same. A dependable semi automatic terminal crimping machine supplier will have strong frames and powerful motors. These parts reduce vibration. They cause less wear. This makes sure that machines work well for a long time. So, for the long term, semi-automatic crimping is a great option.

Production Efficiency for Small and Large Factories

These Semi Automatic Terminal Crimping Machine are very useful for businesses of all sizes, from small to large. A benchtop wire crimping machine can help you save space. The tables are clean. Fits into tight spaces. The workspace is kept clean. Larger models can handle more production. They don’t stop for hours and hours of running. They move at a constant speed. Semi-automatic machines are great for moving from fully automatic crimping machine assembly lines to manual tools because they are balanced. Factories can grow slowly without much risk.

Safety and Operator Comfort Design

The main goal of modern crimping machines is to keep workers safe. Protective gloves are better for your hands. Use foot pedals to lessen the strain on your hands. It’s easy to get to the buttons. The noise level is kept low while people are working. A Semi Automatic Mute Terminal Crimping Machine is perfect for clean, quiet spaces. Workers can relax better when there is less noise. This helps them focus. A nice place to work makes you more accurate. More accuracy leads to better products. This layout lets workers put in long hours without hurting their health or productivity.

Application Areas Across Industries

These Semi Automatic Terminal Crimping Machine tools are used by a lot of different fields. They are often used in factories that make electronics. They are used in the production lines for making household appliances. They are used in the wiring systems of cars. They also help build control panels. Power cabinets are the same way. Several manufacturers pair them with an Automatic wire crimping machine for jobs that require a variety of techniques. This system makes it possible to have flexible production. You can work with small batches. It can also handle large orders. This makes planning production a piece of cake.

T-CH10 Crystal Head RJ45 Terminal Crimping Machine

High Precision for Network Cable Work

The T-CH10 was made just for RJ45 crystal head plugs. It makes crimps that are clean and strong. All of the pins stay under the same amount of pressure. The results are the same no matter which cable you use. So, you can keep the signal strong. It helps keep bad connections from happening. It is a common choice for data cable production lines. As a Best Semi Automatic Terminal Crimping Machine, it makes batch work easy. You can set it up quickly. It’s easy to use every day. Even though there aren’t many mistakes, output stays high.

Key Features

- The crimp finish is very clear.

- A steady way to control pressure

- Small work area

- Low power use all the time when working

- Long-lasting with little maintenance

TM-2.0T Semi Automatic Mute Wire Terminal Crimping Machine

Quiet Power for Daily Production

The TM-2.0T is both strong and comfortable. It works perfectly through all of the cycles. Compared to regular versions, it works almost silently. Our Semi Automatic Mute Terminal Crimping Machine works best when you work long hours. There isn’t much noise in the workshop. The crimp force is still very strong and steady. Many Semi Automatic Mute Terminal Crimping Machine Suppliers strongly suggest this type for work areas that need to be clean and quiet. Workers say they are less tired. The output stays the same all day.

Key Features

- Better way to control the mute

- The crimp quality is always the same with each run.

- Changing dies quickly and easily

- Strong steel framework for the apparatus

- Easy and safe footing

T-FW320 Semi-automatic Flat Cable Terminal Crimping Machine

Reliable Solution for Flat Cables

The T-FW320 is perfect for flat and ribbon wires. It keeps the wires in perfect alignment while crimping. Crimps stay even and sharp. There is no wire shift. This machine is great for making a lot of things at once. It works great with an Automatic Wire Stripping and Crimping Machine. This combination saves time. Costs for labor go down. It makes production go more smoothly. Many users depend on it as a dependable semi auto crimping machine supplier when it comes to flat cable work.

Key Features

- Full flat cable support

- Stable and smooth feed system

- High repeat accuracy

- Easy daily cleaning and care

- Durable body for long life

| Model | Best Use | Noise Level | Work Type |

| T-CH10 | RJ45 network plugs | Low | Data cables |

| TM-2.0T | General terminals | Very Low | Industrial wiring |

| T-FW320 | Flat cables | Low | Ribbon cables |

Semi Automatic vs Fully Automatic Systems

A semi automatic terminal crimping machine gives better control to the operator. A full Automatic crimping machine focuses on speed and volume. Semi-automatic machines cost less to buy. They need less floor space. They allow manual wire feeding. This is useful for custom jobs. It is also useful for small batches. Many factories start with semi-automatic systems. Later, they upgrade to full automation as demand grows.

Maintenance Tips for Long Machine Life

- Clean crimping dies every day

- Check pressure settings weekly

- Oil moving parts on schedule

- Train operators carefully

- Replace worn parts early

Semi Automatic Terminal Crimping Machine Price

The Semi automatic terminal crimping machine price depends on many factors. Motor power affects cost. Crimp force level also matters. Mute models usually cost more. High-tonnage models also cost more. Still, these machines give strong value over time. Lower waste saves material cost. Stable quality reduces rework. Long machine life lowers repair costs. This makes the investment very smart for factories.

Choosing a Trusted Supplier

Always choose a reliable semi automatic terminal crimping machine supplier. Good suppliers offer training support. They provide spare parts. They offer fast service help. A trusted semi auto crimping machine supplier ensures smooth setup and long-term use. Quality support protects your production line. It also protects your budget.

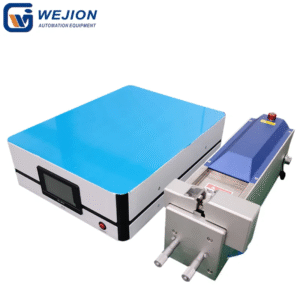

Recommended Manufacturer Website

Kunshan Weijiang Automation Equipment Co., Ltd. offers a wide range of professional crimping solutions. The company focuses on industrial accuracy. It also focuses on operator safety. It serves factories around the world. Their machines meet modern production standards. They support long-term industrial growth.

FAQs

What is a semi automatic terminal crimping machine?

It is a machine that crimps terminals using motor power. The user feeds the wire by hand. The machine applies stable pressure for each crimp.

Who should use a Semi Automatic Electric Terminal Crimping Machine?

Small and medium factories benefit the most. Custom wire processing shops also gain strong value from it.

Can it work with an Automatic wire crimping machine line?

Yes. Many factories use both systems together. This provides a flexible, efficient production flow.

Is a mute model worth it?

Yes. A Semi Automatic Mute Terminal Crimping Machine improves comfort. It reduces noise. It helps workers focus better.

How do I choose the best model?

Check your wire type. Check daily output needs. Choose the Best semi automatic terminal crimping machine that fits your work clearly.