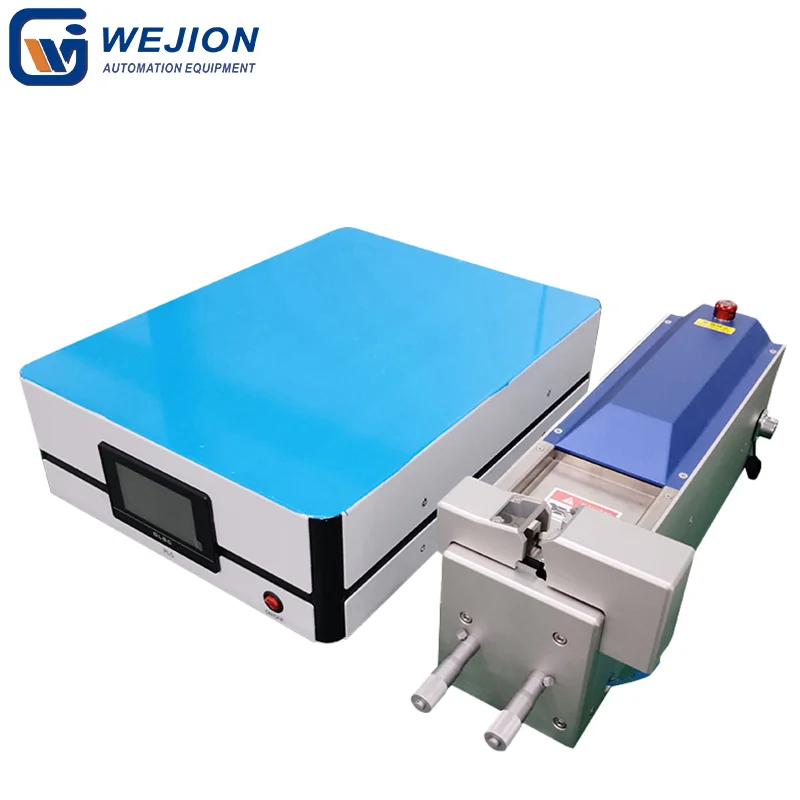

Use a semi-automatic soldering machine with temperature control to make sure that your solder joints are always strong. The temperature stays the same throughout the work cycle. Constant heat protects fragile parts like small pins, short cables, and electronics. There is less of a chance of getting burn scars and weak joints. It’s easy to learn how to use the machine. It is easy for anyone to use, from beginners to experts. Things you do every day get easier and faster. A lot of mistakes that people make go away. It looks like every solder point is clean, even, and won’t cause any problems after a long time of use.

Built for Modern Wire and Cable Work

This equipment can handle all of today’s wire and cable needs. It works with a lot of small connections, signal lines, and USB cables. It makes it possible to do the same high-quality work over and over again. Because it always makes the same amount of stuff, factories choose it every day. The main things that good suppliers of semi-automatic soldering machines care about are how long they last and how little maintenance they need. The outside design is strong and neat. There is a control panel that is easy to understand. It’s easy to press and read the buttons. There isn’t much training for workers. Production can start right away.

Why Temperature Control Matters

To solder well, you need to be able to control the heat very well. Too much heat can damage or melt wire cores and coverings. If you don’t get enough heat, your joints may become weak and loose. A semi-automatic soldering machine’s job is to keep temperatures exactly where they need to be. Built-in sensors keep an eye on the solder tip all the time. The system quickly changes when it needs heat. This keeps all the joints the same size and strength. The product’s quality stays the same throughout. This is very important for buying in bulk.

Perfect for USB Type-C Cable Assembly

The method is great for working with small pins. It is easy to use with an automatic USB Type-C wire soldering machine. The USB Type-C pins are kept clean and in good shape. There is the same amount of solder on each pin. It is also good for use in the assembly line of semi-automatic USB Type-C cable soldering machines. You don’t have to give up quality for speed. The number of mistakes is still low. This lets businesses meet their tight delivery deadlines while still keeping up with the fast-paced market.

Key Benefits at a Glance

- Consistent and exact control of heat

- Simple setup for daily tasks

- Junctions that are clean and shiny with solder

- There are fewer repairs and rework.

- No risk to thin or delicate wires

- Longer life for the machine

Wide Range of Soldering Modes

The device can handle different types of soldering. It might work as a semi automatic dip soldering machine for locations with deep solder. It also works well as a batch work dip soldering machine semi automatic. For specialty joins, it aids in semi automatic soak soldering machine work. Because it has a wide range, one machine can do a lot of different things. Factories don’t need machines. This action saves both space and money. Planning work becomes easier.

Simple Design for Daily Use

The semi-automatic soldering machine has a strong and dependable body. It’s not a problem to work long hours. Everything on the control panel is tidy and easy to see. It’s easy to figure out how to use knobs and buttons. It’s easy for employees to learn how to do the job. The smart layout makes it easier to fix wrong settings. For both small workshops and big businesses, this is one of the best semi automatic soldering machine options. It’s easy to keep up with regular maintenance. Cleaning doesn’t take long. The costs of upkeep are very low.

Quality Output for Mass Production

It looks like the size and shape of each solder joint are the same. The time it takes for solder to flow and heat stays the same. This is important for mass production lines. This design principle is followed by a lot of companies that make semi-automatic soldering machines. It can help meet strict quality standards around the world. Even though they work long hours, the output stays the same. The equipment keeps its accuracy over time. Customers always get the same things with each batch.

Cost Value and Pricing Insight

The price of a semi-automatic soldering machine depends on the size and features of the control system. Managing temperature is very useful. There is less waste of solder. There is less damage to the product. The cost of repairs goes down over time. The tools also help lower the cost of labor. When you think about using it for a long time, the ROI is pretty good. This makes it a great choice for adding to factories and starting new assembly lines.

Ideal Choice for China Supply Chains

One of the best things about type-c semi-automatic soldering machines made in China is that they can get supplies quickly. Finding replacement parts is easy. Get help with tech problems right away. This makes it possible for production lines to keep running smoothly. The shipping time is short. The service has a lot of support. Planning is easier, and there isn’t much downtime.

Recommended Ultrasonic Welding Machines

WC-U20 Ultrasonic Wire Harness Welding Machine

This WC-U20 Ultrasonic Wire Harness tool connects wires without using heat. It works by sending out waves of high-frequency sound. The strands of wire stick together very tightly. Joints that are strong and clean. It’s great for making wire harnesses. It uses less energy. People who work with it don’t have to worry. The rate of operation is steady and quick.

WU-HN0520 Ultrasonic Cable Welding (0.5–20mm²)

This WU-HN0520 Ultrasonic Cable Welding type is best for cables that are small to medium in size. Your wires could be anywhere from half an inch to twenty millimeters wide. The area around the weld is still tight and whole. It is helpful for both power cables and car cables. Setting it up is quick and easy. Long runs do not lower the quality of the output.

WU-HN2070 Ultrasonic Cable Welding Machine (20–70mm²)

These WU-HN2070 Ultrasonic Cable heavy-duty wires are just right for this device. It can handle wire diameters from 20 to 70 mm². A strong and long-lasting building. Good for working with high-power cables. Weld joints stay strong even after long periods of use. This is the best tool for tough jobs.

Reliable Brand for Semi-Automatic Soldering Machine

For reliable semi-automatic soldering machines and support, Kunshan Weijiang Automation Equipment Co., Ltd is the best website. The company offers a wide product range. Quality checks are strict. Technical support is strong. After-sales service is reliable. Buyers can feel safe with long-term cooperation.

A temperature-controlled Semi-automatic Soldering Machine improves speed, safety, and quality. It fits modern cables, and USBs work very well. When combined with ultrasonic welding machines, factories gain a full and flexible solution. For trusted supply and support, Kunshan Weijiang Automation Equipment Co., Ltd. is a reliable partner.

FAQs

What is a Semi-automatic Soldering Machine?

It is a machine that helps solder wires using a set heat and time. It reduces manual effort and errors.

Is it good for USB Type-C cables?

Yes. It works very well with fine pins and small USB wires.

Can one machine support many solder styles?

Yes. It supports dip, soak, and normal soldering modes.

Is it safe for new workers?

Yes. Controls are simple and clear. Training is fast.

Why is temperature control important?

It keeps joints strong and avoids wire damage.