Cables power almost everything we use. From large industries to daily devices, strong and well-prepared cables are at the heart of reliable connections. Biting these cables by hand causes time, energy, and often mistakes. This is why the automatic large cable cutting machine has become an important tool in many industries.

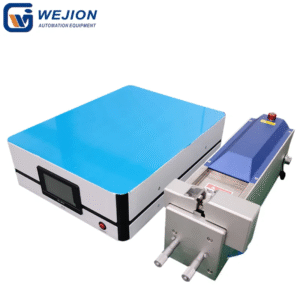

Full Automatic Large Cable Cutting Machine (CS-8150Q)

The CS-8150Q is a full-automatic large cable cutting machine, strong, sharp and accurate. It is designed to cut thick cable and multi-core wires with very low manual work. This makes a great option for busy factories and electrical workshops.

High-Performance Cutting

This heavy duty cable cutting equipment can cut cables up to 33mm thick and cross-sections up to 150mm². It can also be customized for larger sizes. The cutting length ranges from 1mm to 99,999mm. Every cut is highly accurate with a tolerance of only 0.002*L. The 16-wheel belt system makes sure wires stay smooth without scratches or marks.

Speed and Technology

The CS-8150Q can reach up to 1800 cuts per hour, which helps save time on big jobs. It uses high-speed steel blades that stay sharp and strong. The cutting system is driven by a servo motor, which gives steady and precise results. You can also choose a full servo upgrade for even better accuracy.

Flexible Use

This precision cable processing system works with many kinds of cables, including special ones. It is fully automatic, so it reduces handwork, saves labour, and improves speed. The CS-8150Q is a reliable solution for modern cable cutting needs.

Automatic Cable Cutting Technology Working Principle

The working principle of an automatic large cable cutting machine is simple but effective.

The cable is fed into the machine through a guiding system. Then, sensors measure the length and diameter. Once the settings are in place, the machine uses a sharp blade and controlled pressure to cut the cable cleanly.

Many machines use servo motors or stepper motors to ensure the feeding process is smooth. This avoids pulling or damaging the cable. The cutting itself is done by hardened blades that can handle both soft and hard cable materials.

What makes the process special is its precision. The automatic wire and cable cutter repeats the same length again and again with little to no error. This ensures uniformity across all cable pieces. Some machines also include automatic stripping functions, which prepare the cable ends for further processing.

Features and Technical Specifications

Modern automatic large cable cutting machines come with several smart features.

One key feature is digital control systems. Operators can input the exact length and quantity needed, and the machine delivers it without error.

Another feature is high-speed performance. These Industrial cable cutting machines have the capacity to process hundreds or even thousands of cables every hour, depending on the model. They are therefore perfect for factories with high production needs.

The technical specifications often include:

- Cutting range for large cable diameters.

- Precision tolerance levels, often within ±0.1mm.

- Powerful motors to feed and cut thick cables smoothly.

- Touchscreen control panels for easy setup and monitoring.

Another crucial component of the design is safety. To keep operators safe, many machines incorporate overload protection, emergency stop buttons, and protective coverings. They are also simple to integrate into production lines due to their small size.

Advantages of Using a Large Cable Cutting Machine

The advantages of an automatic large cable cutting machine are clear.

- The first advantage is speed. What used to take hours with manual tools can now be done in minutes. This saves labour costs and boosts overall production.

- The second advantage is accuracy. Every cable is cut to the exact length required. This avoids waste and ensures better performance in electrical systems.

- Another benefit is safety. Manual cutting of large cables is not only tiring but also risky. With automatic machines, operators no longer need to use sharp hand tools. The machine does the hard work, reducing the chance of accidents.

- There is also the advantage of consistency. Every piece of cable looks and performs the same. This is very important for industries such as motor vehicles and electronics, where small mistakes can also cause failures.

- These multi-core cable cutting technologies are cost-effective. Although the initial investment may seem higher, savings in time, labour and material make it worth it.

Applications in Electrical and Industrial Cable Processing

In many areas, automatic large cable cutting machines are used. In the electrical industry, they prepare cables for power distribution, wiring systems and home appliances. Clean and accurate cuts ensure better current flows and reduce energy loss.

In the motor vehicle industry, they are important for creating a wire harness that connects different parts of a vehicle. From the dashboard to the engine system, the exact cable length is required everywhere.

The telecom industry is also very beneficial. To maintain the quality of the signal, large cables used in the communication network should be cut properly.

Construction companies also use these machines. In large buildings, cable miles are required for electricity and communication systems. Machines help cut down and quickly prepare them in sites or factories.

Materials and Technology Behind the Machine Design

The durability of an automatic large cable cutting machine depends on the materials used.

The body is usually designed to provide strength and stability from hard steel or aluminium alloys. Cutting blades alloys are prepared from steel or tungsten carbide, which ensures that they remain sharp and resist wear.

On the technology side, these electric power cable cutting tools often use all-in-one systems for feeding and cutting. It provides smooth speed and high accuracy. Sensors are made to detect cable position, diameter and cutting length.

Modern models may also have PLC systems and touchscreen displays for easy control. Some advanced machines also allow data tracking, so operators can monitor performance in real time and output.

How to choose the best cutting machine

Choosing the correct automatic large cable cutting machine depends on your needs.

- Consider the type of cables you process. Some machines handle copper or aluminium cables only, while others may manage multi-core or armoured cables.

- Think about the amount of production. If your factory handles large batches daily, you need a high-speed machine with heavy capacity. For small runs, a compact model may be sufficient.

- Look at the exact requirements. If your industry demands a very tight tolerance, invest in a machine with advanced control systems.

- Don’t forget to check the ease of operation.A control room that is easy to use speeds up employee training and lowers error rates.

- Assess the post-purchase assistance.

Premium Quality Large Cable Cutting Machine supplier

When it comes to finding the best automatic large cable cutting machines, a reliable name is Kunshan Weijiang Automation Company. The company specializes in wiring treatment and utilisation of mounting machines and solutions, and is known for distributing premium quality products worldwide.

They provide machines, strong materials, technology and easily used functions. Their machinery is designed for areas that require accuracy and speed. Their high-speed cable cutting solution covers a wide range of applications from electronics to cars.

They guarantee that companies will benefit as much as possible from their investments by providing first interest rate assistance, training and after-sales service.

The Kunshan Weijiang Company is a dependable partner for businesses wishing to modernise their cable processing lines since it offers both affordable pricing and innovation.